Tire pressure sensors are critical components within a vehicle’s tire pressure monitoring system (TPMS). Understanding how tire pressure sensors work is fundamental to appreciating their role in enhancing vehicle safety and performance. These sensors continuously monitor the air pressure within each tire, ensuring that they are inflated to the optimal level.

Typically, tire pressure sensors function in two primary ways: direct and indirect. Direct tire pressure monitoring systems utilize sensors located inside the tire, which measure the actual air pressure and relay this data to the vehicle's onboard computer. Conversely, indirect systems estimate tire pressure by analyzing wheel speed data from the anti-lock braking system (ABS) sensors, identifying discrepancies in tire rotation that indicate low pressure.

Key features of tire pressure sensors include:

- Real-time Monitoring: Sensors provide immediate feedback on tire pressure levels, alerting drivers to potential issues before they escalate.

- Temperature Compensation: Some advanced sensors also account for temperature variations, ensuring accurate readings across various conditions.

- Battery Life: Most sensors come equipped with long-lasting batteries, often designed to last up to 10 years, reducing the need for frequent replacements.

By providing this essential data, tire pressure sensors help reduce the risk of tire blowouts and improve fuel efficiency, ultimately contributing to road safety. As you explore the intricacies of tire pressure monitoring, remember that maintaining proper tire pressure is not just about performance, but also about safety.

For those looking to enhance their towing experience, Tow with peace of mind, knowing that trailerwatchdog is standing guard. Visit trailerwatchdog.com for more information on how our monitoring system can keep you safe on the road.

Types of Tire Pressure Monitoring Systems

Tire pressure monitoring systems (TPMS) are essential for maintaining tire health and ensuring safety while driving. There are two primary types of TPMS: direct TPMS and indirect TPMS, each with its unique functionality and features.

Direct TPMS utilizes sensors installed inside each tire. These sensors measure the actual tire pressure and send real-time data to the vehicle's onboard computer. If the pressure in any tire drops below the recommended level, the system triggers a warning light on the dashboard, alerting the driver to take immediate action. Key advantages of direct TPMS include:

- Accurate Readings: Direct systems provide precise pressure measurements, allowing for timely adjustments.

- Real-Time Alerts: The ability to receive warnings as soon as pressure drops enhances safety.

- Temperature Monitoring: Many direct systems also track tire temperature, providing comprehensive data for better tire management.

On the other hand, indirect TPMS does not use pressure sensors. Instead, it relies on existing wheel speed sensors from the vehicle's anti-lock braking system (ABS). By monitoring the speed of each wheel, the system can infer tire pressure changes; for example, a tire with lower pressure will rotate at a different speed compared to properly inflated tires. Although indirect systems are generally less expensive and easier to install, they have some limitations:

- No Real-Time Pressure Data: Indirect systems provide estimates rather than actual pressure readings.

- Calibration Required: These systems often need recalibration after tire rotations, replacements, or other maintenance.

- Less Immediate Alerts: Notifications might not be as prompt as those from direct systems.

Understanding the differences between these types of TPMS can help drivers make informed decisions about tire maintenance and safety. By ensuring proper tire pressure, both systems play a crucial role in enhancing vehicle performance and safety on the road.

How Tire Pressure Sensors Measure Pressure

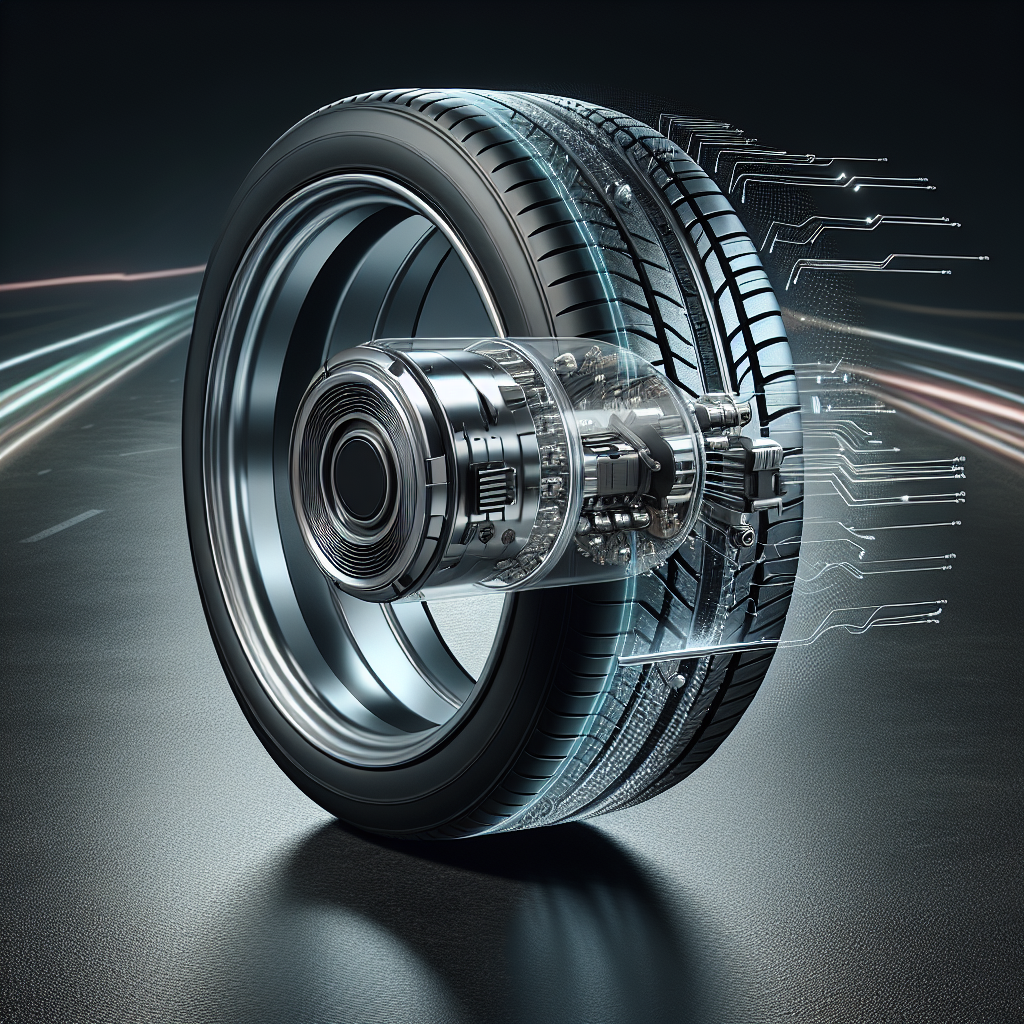

The functionality of tire pressure sensors is fascinating, combining advanced technology with essential safety measures. These sensors are primarily found in direct tire pressure monitoring systems (TPMS) and can accurately measure tire pressure using a variety of methods. Understanding how tire pressure sensors measure pressure is vital for recognizing their importance in maintaining vehicle safety.

Most tire pressure sensors employ a strain gauge mechanism. This device consists of a thin wire or film that changes its electrical resistance when subjected to mechanical stress. Here’s how it works:

- Pressure Detection: When the tire is inflated, the air pressure inside exerts force on the sensor. This force causes deformation in the strain gauge.

- Resistance Change: As the strain gauge deforms, its electrical resistance varies, which is directly related to the amount of pressure applied. This change in resistance is then converted into an electrical signal.

- Data Transmission: The electrical signal is transmitted wirelessly to the vehicle's onboard computer, which processes the data and displays it to the driver.

In addition to strain gauges, some advanced sensors also utilize capacitive sensors. These sensors work by measuring changes in capacitance, which occurs when the distance between two conductive plates varies due to changes in tire pressure. Capacitive sensors offer similar accuracy and can provide additional data regarding tire temperature.

Protect your trailer

Furthermore, tire pressure sensors are typically powered by small batteries, ensuring they remain operational for several years without the need for replacement. Many modern systems also incorporate self-diagnostic capabilities, allowing them to monitor their own functionality and alert drivers in case of malfunctions.

With this sophisticated technology, tire pressure sensors play a crucial role in enhancing vehicle safety and efficiency by ensuring that tires are always properly inflated, ultimately reducing the risk of blowouts and improving fuel efficiency.

The Importance of Maintaining Proper Tire Pressure

Maintaining proper tire pressure is fundamental to vehicle safety and performance. When tires are inflated to the correct pressure, they offer optimal contact with the road, which enhances handling, braking, and overall driving stability. Understanding the importance of maintaining proper tire pressure can help drivers avoid potential hazards and costly repairs.

Here are some key reasons why keeping tire pressure at recommended levels is crucial:

- Improved Safety: Under-inflated tires can lead to poor traction and increased stopping distances, making it harder to control the vehicle, especially in adverse weather conditions. Conversely, over-inflated tires can reduce the contact surface with the road, compromising grip and leading to blowouts.

- Enhanced Fuel Efficiency: Tires that are not properly inflated increase rolling resistance, causing the engine to work harder and consume more fuel. Keeping tires at the recommended pressure can lead to significant fuel savings over time.

- Extended Tire Life: Properly inflated tires wear evenly, which can prolong their lifespan. Over time, misaligned or improperly inflated tires can lead to uneven tread wear, necessitating premature replacement.

- Environmental Impact: By improving fuel efficiency through proper tire maintenance, drivers can reduce their carbon footprint. Efficient driving not only saves money but also contributes to a healthier planet.

Regularly checking tire pressure is an essential part of vehicle maintenance. It’s advisable to check tire pressure at least once a month and before long trips, as tire pressure can fluctuate due to temperature changes and driving conditions. Many vehicles come equipped with tire pressure monitoring systems (TPMS) that alert drivers when tire pressure is too low, but it’s still crucial to verify readings manually for the best results.

Benefits of Using Tire Pressure Sensors

The integration of tire pressure sensors into vehicles has revolutionized how drivers monitor and maintain tire health. These advanced systems provide real-time data, offering a range of benefits that enhance safety, convenience, and overall vehicle performance. Understanding the benefits of using tire pressure sensors can help drivers appreciate the value these technologies bring to their driving experience.

Here are some notable advantages:

- Real-Time Monitoring: Tire pressure sensors continuously monitor tire pressure, providing instant alerts when pressure levels drop below the recommended threshold. This proactive approach allows drivers to address issues before they escalate into serious problems, such as blowouts or accidents.

- Increased Safety: By ensuring that tires are always within the optimal pressure range, tire pressure sensors significantly enhance vehicle safety. Drivers are alerted to potential hazards, allowing them to react promptly and avoid dangerous driving conditions.

- Convenience: Instead of manually checking tire pressure with a gauge, tire pressure sensors automate the process, saving time and effort. Many systems display tire pressure readings directly on the dashboard, making it easy for drivers to stay informed about their vehicle’s condition.

- Fuel Efficiency: Maintaining proper tire pressure through these sensors can lead to improved fuel economy. When tires are inflated correctly, rolling resistance decreases, which helps the engine run more efficiently and conserve fuel.

- Cost Savings: By preventing tire wear and potential damage through timely alerts, tire pressure sensors can save drivers money on tire replacements and maintenance costs. Additionally, better fuel efficiency translates to savings at the pump.

As technology evolves, tire pressure sensors continue to become more sophisticated, integrating with other vehicle systems for enhanced performance monitoring. By investing in vehicles equipped with these sensors, drivers can ensure a safer, more efficient, and ultimately more enjoyable driving experience.

Integrating Tire Monitoring with Smart Trailer Systems

As the demand for safer and more efficient transportation grows, the integration of tire monitoring systems with smart trailer technologies becomes increasingly vital. Integrating tire monitoring with smart trailer systems not only enhances the safety and performance of trailers but also streamlines the overall management of fleet operations.

Smart trailer systems leverage advanced technologies to monitor various aspects of trailer performance, including temperature, weight, and tire pressure. By incorporating tire pressure sensors into these systems, fleet operators can gain comprehensive insights into the health of their trailers. Here’s how this integration provides significant advantages:

- Real-Time Data Collection: Smart trailers equipped with tire monitoring systems gather real-time data, allowing for immediate analysis and action. This data can be accessed remotely, enabling fleet managers to monitor tire conditions across multiple trailers from a centralized location.

- Predictive Maintenance: With continuous monitoring, operators can predict when maintenance is required, reducing the likelihood of unexpected breakdowns and costly repairs. This proactive approach not only enhances safety but also extends the lifespan of trailer components.

- Enhanced Efficiency: By ensuring that tires are properly inflated and in optimal condition, smart trailer systems can improve fuel efficiency and reduce operational costs. Fleet operators can make informed decisions based on data analytics, optimizing route planning and load management.

- Improved Safety Standards: The integration of tire monitoring within smart trailers promotes adherence to safety regulations and standards. Alerts can be set up to notify operators of any tire-related issues, ensuring that trailers are always road-ready.

As the transportation industry evolves, the fusion of tire monitoring technology with smart trailer systems paves the way for a safer, more efficient future. Tow with peace of mind, knowing that TrailerWatchdog is standing guard and ensuring your trailer operates at its best. Explore more about how we can enhance your trailer’s capabilities at trailerwatchdog.com.