In the realm of trailer safety and efficiency, one technological advancement stands out: the trailer hub temperature sensor. These sensors play a crucial role in monitoring the temperature of trailer hubs, which are vital components of any trailer. By providing real-time data on hub temperature, these sensors help prevent potential failures that could lead to catastrophic events on the road.

Understanding the functionality of trailer hub temperature sensors is essential for anyone involved in the transportation industry. These sensors work by detecting the heat generated within the trailer hubs during operation. Elevated temperatures often indicate friction or malfunction, signaling the need for immediate attention. By catching these signs early, drivers and fleet managers can address issues before they escalate, ensuring the safety of both the cargo and the vehicle.

Moreover, the benefits of implementing trailer hub temperature sensors extend beyond just safety. They play a significant role in enhancing the overall efficiency of trailer operations. With accurate temperature readings, operators can optimize maintenance schedules, reducing downtime and repair costs.

With these advantages in mind, it’s clear that integrating a trailer hub temperature sensor into your fleet can be a game-changer. Tow with peace of mind, knowing that trailerwatchdog is standing guard.

Understanding How Trailer Hub Temperature Sensors Work

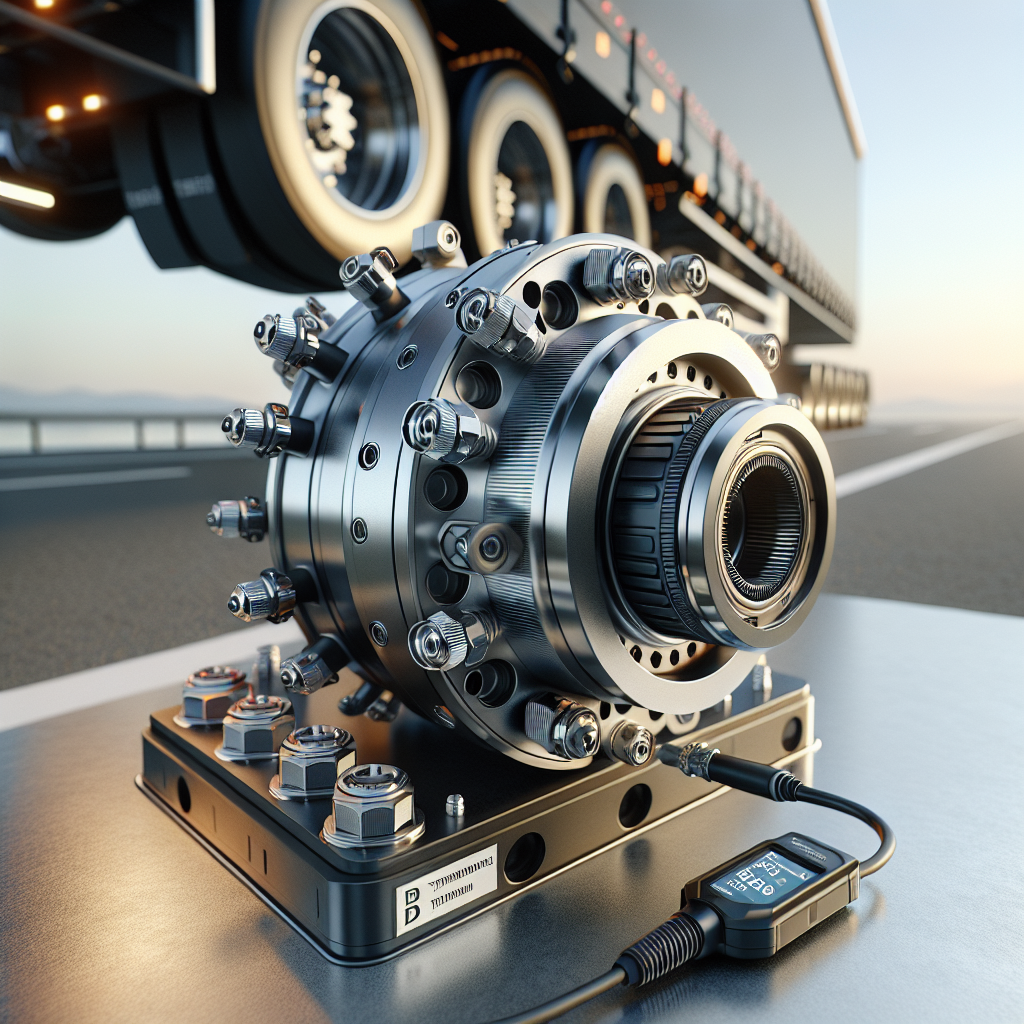

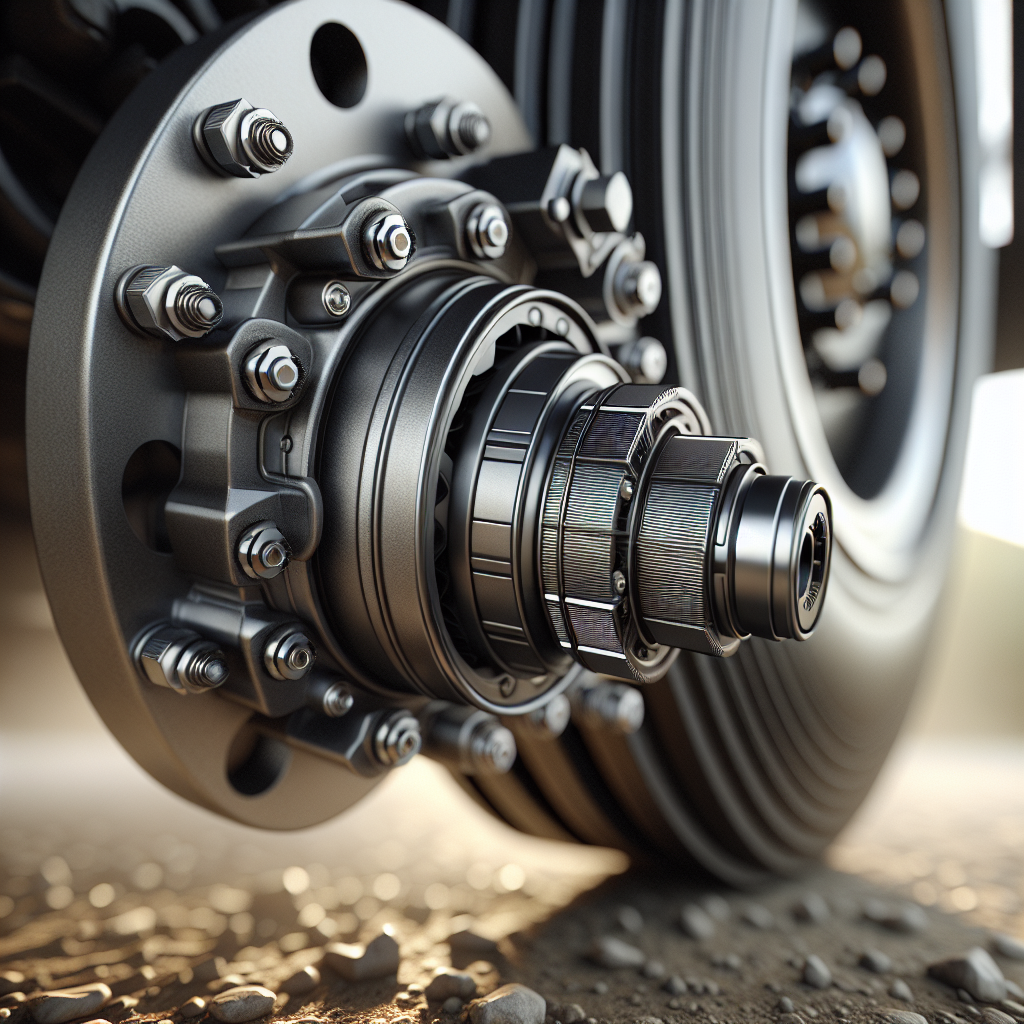

To fully appreciate the value of trailer hub temperature sensors, it's important to delve into their operational mechanics. These sensors are designed to monitor the temperature of the hubs, which are critical points where the axle connects to the wheel. When a trailer is in motion, friction between the wheel bearings and the axle generates heat. If the temperature rises beyond a safe threshold, it may indicate a problem, such as inadequate lubrication or bearing failure.

The sensors utilize advanced technology, typically including thermistors or infrared sensors, to detect temperature changes accurately. Here's a brief overview of how they function:

- Temperature Measurement: The sensor continuously monitors the hub temperature and sends this data to a central monitoring system.

- Data Transmission: Most trailer hub temperature sensors are equipped with wireless communication capabilities, allowing them to transmit real-time data to fleet managers or drivers via mobile apps or onboard displays.

- Alert System: If the temperature exceeds a predetermined limit, the system triggers an alert, notifying the operator of the potential issue.

This proactive approach enables stakeholders to take immediate action, whether that means pulling the trailer off the road for inspection or performing necessary maintenance. By understanding how these sensors work, operators can better appreciate their role in maintaining safety and efficiency on the road.

Benefits of Using Trailer Hub Temperature Sensors

Incorporating trailer hub temperature sensors into your trailer monitoring system offers numerous advantages that significantly enhance operational efficiency and safety. Here are some key benefits:

Protect your trailer

- Preventive Maintenance: By providing real-time temperature data, these sensors enable operators to detect overheating early. This proactive measure helps in scheduling maintenance before minor issues escalate into costly repairs.

- Reduced Downtime: With instant alerts regarding temperature anomalies, fleet managers can take immediate action to mitigate risks. This leads to less downtime, ensuring that trailers remain operational and productive.

- Improved Safety: Overheating can lead to catastrophic failures, including wheel bearing seizure or even accidents. By monitoring hub temperatures, the risk of such dangerous events is significantly reduced, enhancing overall safety for drivers and other road users.

- Cost Efficiency: Lower repair costs due to early detection of issues and reduced downtime directly contribute to cost savings. Additionally, efficient operation leads to improved overall fleet performance, maximizing return on investment.

- Enhanced Data Insights: The data collected from these sensors can be analyzed over time, providing valuable insights into the performance of trailers. This data can inform future purchases and maintenance schedules, further streamlining operations.

Overall, the integration of trailer hub temperature sensors into your monitoring system is not just a trend; it's an essential step towards modernizing fleet management and ensuring the longevity of your trailers.

Common Applications of Trailer Hub Temperature Sensors

Trailer hub temperature sensors are versatile tools that find applications across various industries, making them invaluable for fleet management and trailer operations. Here are some common applications:

- Logistics and Transportation: In the logistics sector, these sensors are crucial for monitoring the health of trailers during long hauls. They help ensure that cargo is transported safely and efficiently, reducing the risk of delays due to mechanical failures.

- Agriculture: Farmers and agricultural businesses utilize trailer hub temperature sensors to monitor equipment transporting perishable goods. By ensuring optimal operating conditions, they can protect their products and maintain quality.

- Construction: In the construction industry, heavy-duty trailers are often subjected to extreme conditions. Monitoring hub temperatures helps prevent equipment failures that could halt projects and lead to increased costs.

- Recreational Vehicles: Owners of RVs and trailers for recreational purposes benefit from these sensors by ensuring the integrity of their vehicles. This monitoring provides peace of mind, especially during long trips.

- Emergency Services: For emergency response vehicles that rely on trailers to transport essential equipment, hub temperature sensors play a critical role in ensuring that these vehicles are always ready for action.

By employing trailer hub temperature sensors in these diverse applications, businesses can improve operational efficiency, enhance safety, and extend the lifespan of their assets.

Factors Affecting Trailer Hub Temperature Sensor Performance

The performance of trailer hub temperature sensors is influenced by several key factors that can affect their accuracy and reliability. Understanding these factors is essential for optimal sensor performance and effective trailer monitoring.

- Environmental Conditions: Extreme temperatures, humidity, and exposure to contaminants can impact sensor functionality. Sensors designed to withstand harsh environments tend to perform better and provide more accurate readings.

- Installation Quality: Proper installation is crucial for sensor effectiveness. If a sensor is not correctly mounted or positioned, it can lead to inaccurate temperature readings and ultimately compromise system reliability.

- Calibration: Regular calibration ensures that sensors maintain their accuracy over time. Without proper calibration, a sensor's performance may degrade, leading to false readings and unreliable data.

- Trailer Load and Weight Distribution: The weight and distribution of cargo within the trailer can affect the heat generated at the hubs. Heavier loads may cause increased friction and heat, impacting sensor performance and necessitating careful monitoring.

- Maintenance Practices: Regular maintenance of both the trailer and its sensors is vital. Neglecting routine checks and service can lead to sensor failures or inaccurate readings, increasing the risk of catastrophic events.

By acknowledging and addressing these factors, trailer operators can enhance the performance of their hub temperature sensors, ensuring better safety and efficiency during trailer operations.

Future Trends in Trailer Hub Temperature Sensor Technology

The landscape of trailer hub temperature sensor technology is rapidly evolving, driven by advancements in sensor design and connectivity. As the demand for smarter, more efficient trailers increases, several future trends are emerging that promise to enhance monitoring capabilities and overall safety.

- Integration with IoT: The Internet of Things (IoT) is set to revolutionize trailer monitoring. Future sensors will likely integrate seamlessly with IoT platforms, allowing for real-time data collection and analysis. This connectivity will enable fleet managers to monitor hub temperatures remotely, improving decision-making processes.

- Enhanced Data Analytics: With the rise of big data, the ability to analyze temperature data will become more sophisticated. Advanced analytics will help in predicting potential failures before they occur, thereby reducing downtime and maintenance costs.

- Wireless Technology: Future sensors are expected to utilize advanced wireless communication methods, reducing the need for cumbersome wiring. This will simplify installation and maintenance while allowing for more flexible sensor placement.

- Smart Sensors: The next generation of sensors will likely employ machine learning algorithms to learn from historical data, improving their accuracy and response time. These smart sensors will adapt to varying conditions, providing more reliable temperature monitoring.

- Energy Efficiency: As sustainability becomes a priority, future sensors will be designed to consume less power while still delivering high performance. This will be critical for extending the lifespan of batteries in wireless sensors.

These trends indicate an exciting future for trailer hub temperature sensors, paving the way for safer and more efficient trailer operations. Tow with peace of mind, knowing that trailerwatchdog is standing guard.