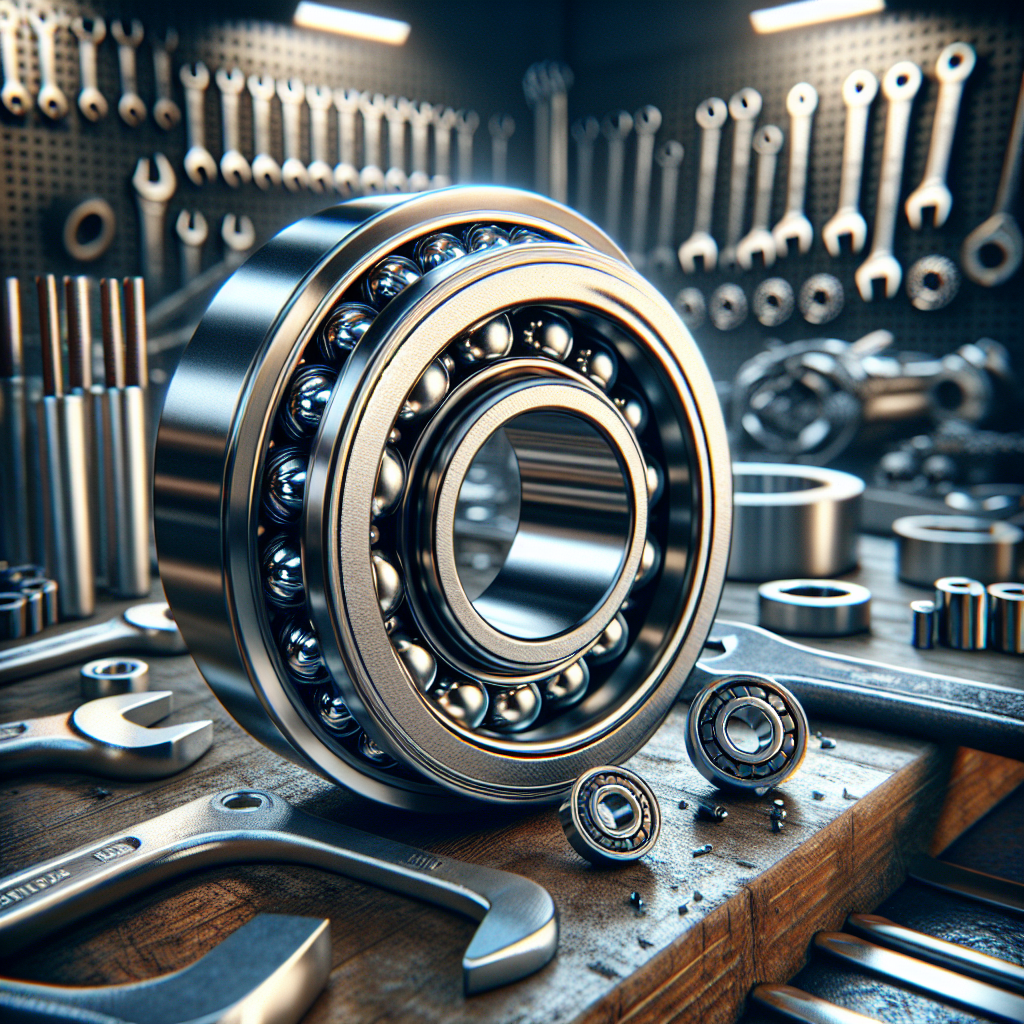

Trailer wheel bearings play a crucial role in the overall functionality and safety of your trailer. These components are responsible for allowing the wheels to rotate smoothly while supporting the weight of the trailer and its cargo. When properly maintained, **_trailer wheel bearings_** ensure a stable connection between the trailer and the towing vehicle, reducing friction and heat that can lead to catastrophic failures.

Understanding the importance of trailer wheel bearings can prevent costly repairs and accidents. Here are key points to consider:

- Weight Distribution: Wheel bearings help distribute the weight evenly across the axle, minimizing the risk of wear and tear.

- Smooth Operation: Properly adjusted bearings reduce friction, allowing for smoother wheel rotation which enhances the overall performance of the trailer.

- Heat Management: Overheating due to improper adjustment can cause bearings to fail, leading to dangerous situations on the road.

- Safety: Well-maintained wheel bearings contribute significantly to the safety of your trailer, ensuring it can handle various road conditions without risk.

Regular inspection and maintenance of your trailer wheel bearings are essential. If you're not familiar with the adjustment process, consider seeking professional assistance. You can also enhance your trailer's safety by integrating advanced monitoring systems, like those offered by TrailerWatchdog. Tow with peace of mind, knowing that trailerwatchdog is standing guard.

Signs That Your Trailer Wheel Bearings Need Adjustment

Recognizing when your trailer wheel bearings need adjustment is vital to maintaining the safety and performance of your trailer. Ignoring the signs can lead to severe damage, increased repair costs, and safety hazards on the road. Here are some key indicators that your trailer wheel bearings may require attention:

- Unusual Noises: If you hear grinding, humming, or whirring sounds while towing, it could indicate that the wheel bearings are worn out or not properly adjusted.

- Excessive Heat: After a trip, if you notice that the wheel hubs are excessively hot to the touch, this is a sign of inadequate lubrication or incorrect adjustment.

- Play in the Wheel: If you feel any play or wobbling in the wheel when you try to move it back and forth, this could suggest that the bearings are loose and need to be adjusted.

- Vibration: Excessive vibrations while towing can be a warning sign that the wheel bearings are not functioning correctly, potentially leading to a dangerous driving experience.

- Visible Damage: Inspect your wheel bearings periodically for any signs of wear, rust, or damage. Any visible issues should prompt immediate inspection and adjustment.

By being vigilant and responsive to these signs, you can ensure that your trailer remains safe and road-worthy, reducing the risk of unexpected breakdowns.

Step-by-Step Guide to Adjusting Wheel Bearings

Adjusting your trailer wheel bearings may seem daunting, but with the right tools and a little patience, you can do it yourself. Follow this step-by-step guide to ensure your wheel bearings are properly adjusted for optimal performance:

- Gather Your Tools: You will need a jack, jack stands, a wrench set, a bearing packer (if necessary), and a torque wrench.

- Lift the Trailer: Securely jack up the trailer and place jack stands under the frame to ensure it is stable. Always prioritize safety when working underneath a vehicle.

- Remove the Wheel: Use the wrench to loosen the lug nuts and remove the wheel to access the hub assembly.

- Inspect the Bearings: Remove the hub and inspect the bearings for any signs of wear or damage. Clean them thoroughly with a suitable solvent.

- Adjust the Bearings: To adjust, tighten the adjusting nut until snug, then back it off slightly. This allows for the necessary play in the bearing.

- Repack the Bearings: If needed, use a bearing packer to add fresh grease to the bearings. Ensure they are adequately lubricated to prevent overheating.

- Reassemble: Carefully reattach the hub, wheel, and lug nuts. Ensure everything is tightened to the manufacturer’s specifications using a torque wrench.

- Lower the Trailer: Once everything is secured, carefully lower the trailer back to the ground.

Regularly adjusting your trailer wheel bearings not only enhances safety but can also extend the lifespan of your trailer components. Following these steps can help you maintain your trailer in top condition.

Protect your trailer

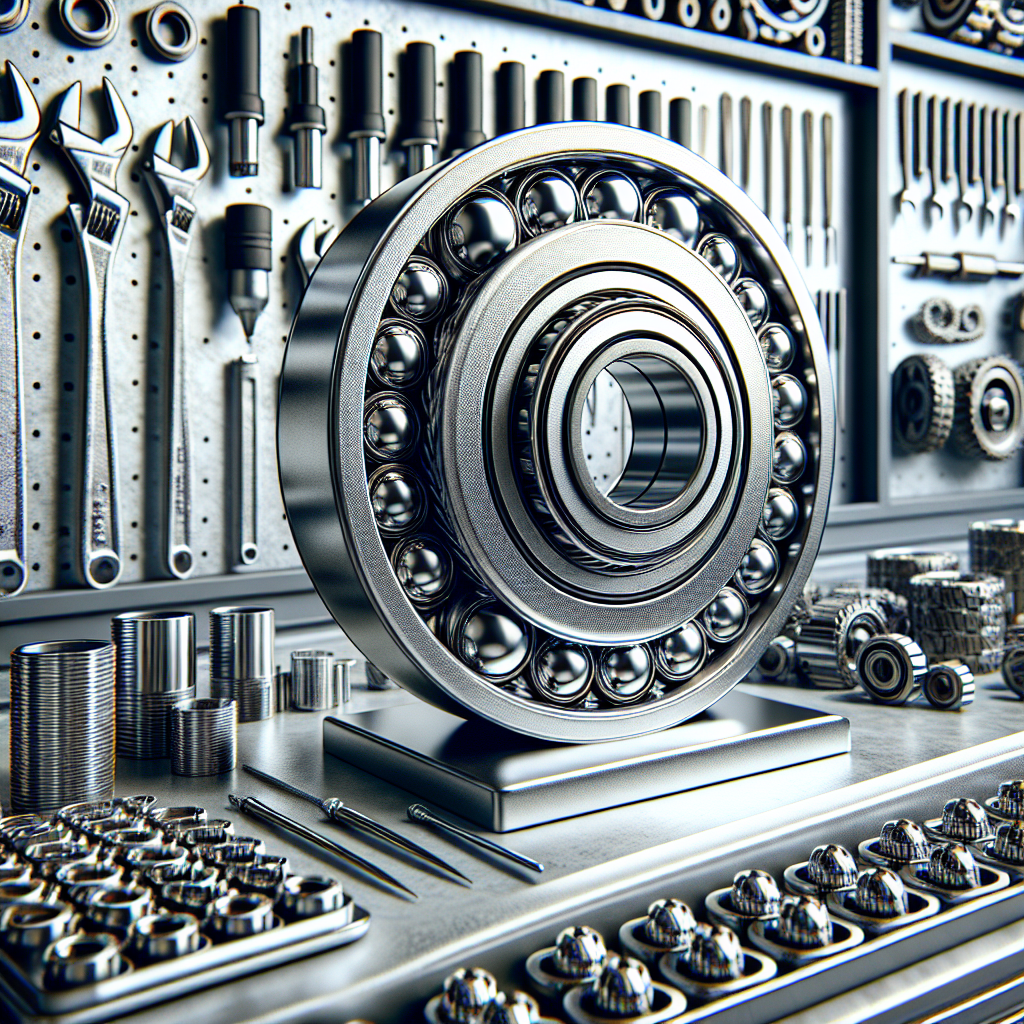

Tools Required for Proper Bearing Adjustment

Having the right tools on hand is crucial for a successful trailer wheel bearing adjustment. The following tools are essential to ensure you can perform the adjustment safely and effectively:

- Jack and Jack Stands: A sturdy hydraulic jack is necessary to lift the trailer, while jack stands provide extra support during the adjustment process.

- Wrench Set: A complete set of wrenches, including socket wrenches, is vital for loosening and tightening lug nuts and bearings.

- Torque Wrench: This tool ensures that you are applying the correct amount of torque to the nuts, which is essential for safety and performance.

- Bearing Packer: A bearing packer makes it easy to apply grease to the bearings, ensuring they are well-lubricated and reducing the risk of overheating.

- Grease Gun: In addition to the packer, a grease gun is useful for adding grease directly into the bearing assembly.

- Cleaning Supplies: Having a solvent and rags for cleaning the bearings and hub assembly ensures that no old grease or debris interferes with the adjustment.

- Safety Gear: Always wear safety glasses and gloves to protect yourself while working on your trailer.

Arming yourself with these tools will not only streamline the trailer wheel bearing adjustment process but will also enhance your overall safety and the longevity of your trailer.

Maintaining Your Trailer Wheel Bearings Effectively

Effective maintenance of your trailer wheel bearings is essential for ensuring safe and reliable towing. Regular maintenance helps prevent wear and tear, ultimately enhancing the lifespan of your trailer's components. Here are some key practices to maintain your trailer wheel bearings effectively:

- Regular Inspections: Periodically check your wheel bearings for signs of wear, damage, or excessive play. Look for grease leaks, discoloration, or unusual noises while the trailer is in motion.

- Greasing Schedule: Establish a routine greasing schedule based on your usage. Ideally, bearings should be packed with fresh grease every 12 months or every 10,000 miles, whichever comes first. Always use the appropriate type of grease for your bearings.

- Check for Overheating: Monitor the temperature of your wheel bearings during trips. If you notice them becoming excessively hot, this could indicate a problem that needs immediate attention.

- Proper Load Distribution: Ensure that your trailer is loaded evenly. Uneven weight distribution can put excessive stress on the wheel bearings, leading to premature failure.

- Seasonal Maintenance: Before and after long trips or seasonal changes, conduct a thorough inspection of your trailer, including the bearing adjustment and lubrication.

By implementing these effective maintenance practices, you can significantly reduce the risk of bearing failure and keep your trailer road-ready.

Common Mistakes to Avoid During Adjustment

When it comes to trailer wheel bearing adjustment, making mistakes can lead to serious safety issues and costly repairs. To ensure that your trailer remains reliable and road-ready, it’s crucial to avoid these common pitfalls:

- Neglecting to Clean: Failing to clean the bearings and the hub before applying new grease can trap dirt and debris, leading to premature wear. Always ensure a clean surface for optimal performance.

- Incorrect Torque Settings: Over-tightening or under-tightening the bearings can result in bearing failure. Always refer to the manufacturer's specifications for the correct torque settings during adjustment.

- Skipping the Test Drive: After making adjustments, it’s important to take your trailer for a short test drive. This allows you to check for any unusual noises or overheating that might indicate an issue.

- Ignoring Signs of Wear: Don't overlook signs of wear or damage during adjustment. If you notice any irregularities, replace the bearings immediately to prevent further damage.

- Using the Wrong Tools: Using improper tools can lead to incorrect adjustments and potential damage. Always use the right equipment designed for trailer maintenance.

By steering clear of these common mistakes, you can ensure that your trailer wheel bearings are adjusted correctly and function optimally. Tow with peace of mind, knowing that trailerwatchdog is standing guard.