For every trailer owner, understanding the basics of trailer wheel bearings is essential to ensure both safety and longevity of your vehicle. Wheel bearings serve as a critical component, allowing the wheels to rotate smoothly while supporting the weight of the trailer. When properly maintained, they can significantly enhance the performance and reliability of your trailer.

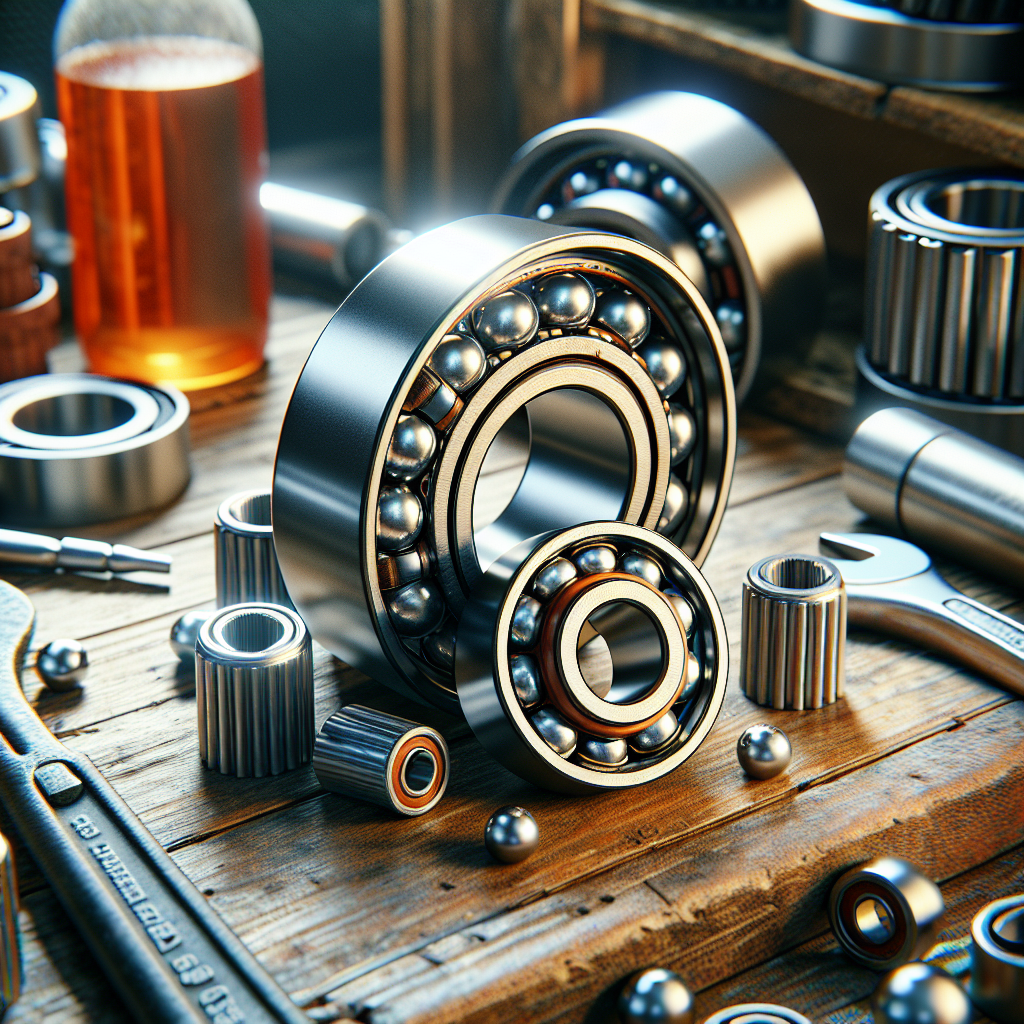

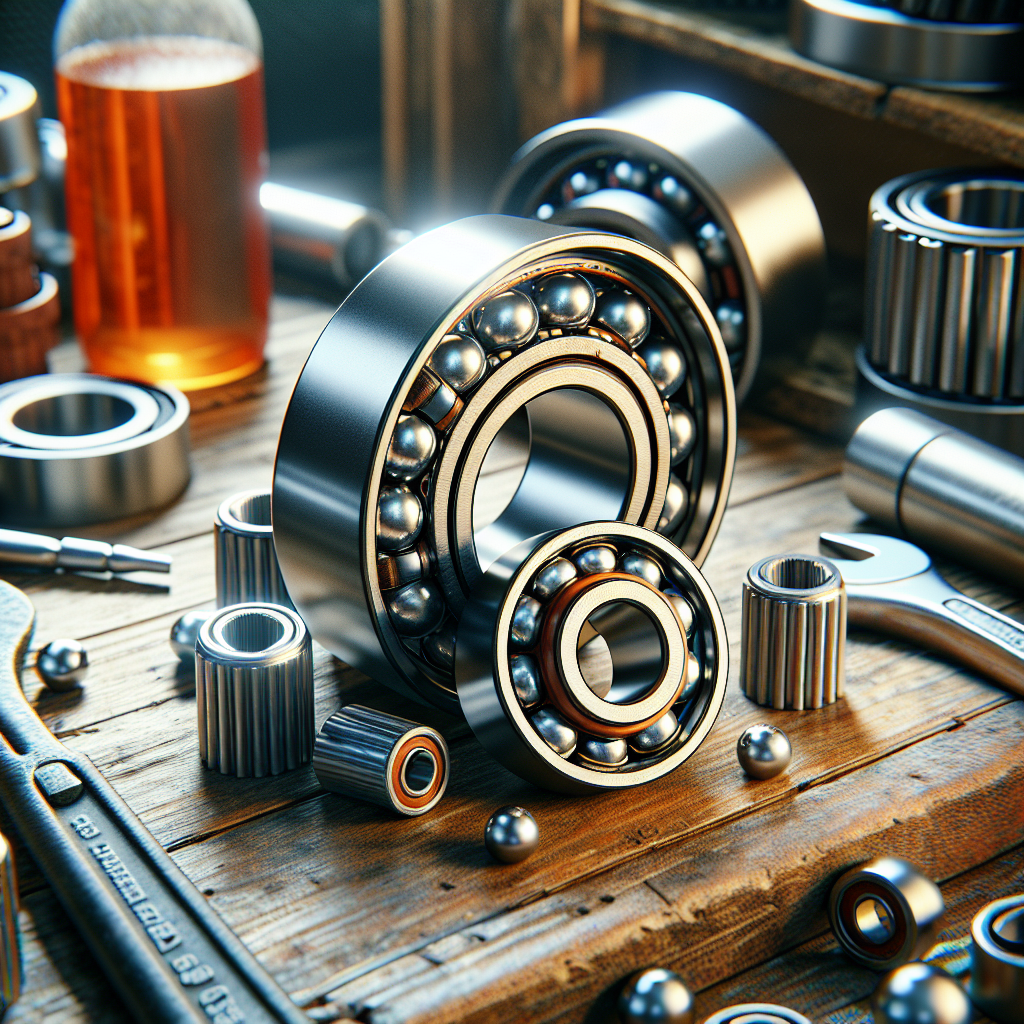

There are two primary types of trailer wheel bearings: roller bearings and ball bearings. Roller bearings are commonly used in heavier trailers due to their ability to handle larger loads, while ball bearings are suitable for lighter trailers. Each type has its own set of specifications and measurements, which can be found in a trailer wheel bearing chart. This chart typically outlines the bearing size, load capacity, and compatibility with different axle types.

Common issues that arise with trailer wheel bearings include:

- Excessive heat buildup due to poor lubrication

- Contamination from dirt and debris

- Wear and tear from improper loading

By regularly inspecting your bearings and referencing the trailer wheel bearing chart, you can prevent catastrophic failures and ensure a smoother towing experience. Don't overlook the importance of maintaining your trailer's wheel bearings!

Tow with peace of mind, knowing that trailerwatchdog is standing guard.

Importance of Regular Trailer Wheel Bearing Maintenance

Regular maintenance of trailer wheel bearings is crucial for several reasons. First and foremost, it directly impacts the safety of your trailer and the vehicles around you. Faulty or worn-out bearings can lead to wheel failure, resulting in loss of control, accidents, or even catastrophic incidents on the road.

Another significant aspect of maintenance is the enhancement of your trailer's performance. Well-maintained wheel bearings ensure smooth wheel rotation, which contributes to better fuel efficiency and overall towing performance. When bearings function optimally, it reduces the strain on other components of the trailer, thus prolonging their lifespan.

Furthermore, regular maintenance can save you considerable costs in the long run. By identifying and addressing minor issues early on—such as excessive play, unusual noises, or overheating—you can avoid extensive repairs or replacements that can arise from neglecting these components. An effective maintenance routine typically includes:

- Regularly inspecting bearing seals for wear and tear

- Checking for adequate lubrication

- Cleaning bearings to remove debris and contaminants

- Repacking bearings with high-quality grease as needed

By prioritizing maintenance, trailer owners can ensure that their equipment remains in optimal condition, reducing the risk of unexpected breakdowns and enhancing overall reliability.

Protect your trailer

Common Types of Trailer Wheel Bearings Explained

Understanding the different types of trailer wheel bearings is essential for any trailer owner looking to maintain their equipment effectively. Each type has its unique characteristics, advantages, and applications. Here are the most common types:

- Ball Bearings: These are the most common type of bearings found in trailers. They consist of a series of balls that provide smooth rotation and are suitable for light to moderate loads. Ball bearings are popular due to their affordability and availability.

- Roller Bearings: Designed to handle heavier loads, roller bearings use cylindrical rollers instead of balls. This design allows for a larger contact area, which reduces friction and increases load-bearing capacity. They are commonly used in larger trailers and heavy-duty applications.

- Needle Bearings: A subtype of roller bearings, needle bearings feature long, thin rollers that can fit into tight spaces. They are particularly useful in situations where high load capacity and space efficiency are required. Needle bearings are often found in specialized trailers.

- Self-Aligning Bearings: These bearings can accommodate misalignment, making them an excellent choice for trailers that may experience uneven loading or rough terrain. They offer flexibility and reduce wear, extending the lifespan of the bearings.

When selecting a bearing type, it's vital to consider the specific needs of your trailer, including load capacity, operating conditions, and maintenance requirements. By choosing the right type of wheel bearing, you can enhance your trailer's performance and longevity.

How to Read and Use a Trailer Wheel Bearing Chart

Reading and utilizing a trailer wheel bearing chart can significantly simplify the maintenance process for trailer owners. These charts provide essential information about various bearing types, sizes, and specifications, enabling owners to make informed decisions. Here’s how to effectively read and use a trailer wheel bearing chart:

- Identify the Bearing Type: The first step is to determine the type of bearing you need. Reference the chart to find the category that matches your trailer's requirements, such as ball, roller, or needle bearings.

- Check Dimensions: Each bearing type will have specific measurements, including inner and outer diameter, width, and sometimes even load ratings. Ensure you cross-reference these dimensions with your existing bearings to guarantee a proper fit.

- Look for Compatibility: Most charts will include compatibility information, indicating which trailer models or axle types can utilize the specified bearing. This is crucial for ensuring that you purchase the correct part.

- Note Maintenance Guidelines: Many bearing charts also provide useful maintenance tips, such as recommended lubrication intervals or common issues to watch for. Familiarizing yourself with these guidelines can help prolong the life of your bearings.

By following these steps, you can effectively navigate a trailer wheel bearing chart, making it a valuable tool in your trailer maintenance arsenal. Accurate information leads to improved performance and safety on the road.

Signs of Trailer Wheel Bearing Failure You Should Know

Being aware of the signs of trailer wheel bearing failure is crucial for maintaining the safety and efficiency of your trailer. Ignoring these signs can lead to catastrophic failures, costly repairs, or even accidents. Here are some key indicators that your trailer's wheel bearings may be failing:

- Unusual Noises: One of the first signs of bearing failure is a noticeable change in sound. You may hear grinding, squeaking, or rumbling noises coming from the wheels while driving, which typically indicates a lack of lubrication or damaged bearings.

- Excessive Heat: If you touch the wheel hub and find it excessively hot, this could be a sign of bearing trouble. Bearings that are failing often generate more heat due to friction, which can lead to further damage.

- Vibration or Wobbling: A trailer that vibrates or wobbles while in motion may have faulty wheel bearings. This instability not only affects handling but can also lead to more severe damage over time.

- Visible Wear and Tear: Regular inspections can help identify signs of wear, such as rust or pitting on the bearing surface. Any visible damage should prompt immediate replacement.

- Grease Leaks: If you notice grease leaking from the wheel hub, this could indicate a seal failure, allowing dirt and moisture to enter and compromise the bearings.

By being vigilant and responsive to these warning signs, trailer owners can prevent significant issues and ensure their vehicles operate smoothly and safely.

Tips for Selecting the Right Trailer Wheel Bearings

Selecting the right trailer wheel bearings is essential for ensuring a safe and efficient towing experience. Here are some tips for selecting the right trailer wheel bearings that can help you make an informed decision:

- Know Your Trailer Type: Different trailers require different types of bearings. Whether you have a utility trailer, boat trailer, or travel trailer, understanding the specific requirements of your vehicle is crucial.

- Check the Load Rating: Ensure that the bearings you select can handle the weight capacity of your trailer. Each bearing has a load rating, and exceeding this limit can lead to premature failure.

- Consider the Environment: If you frequently travel in harsh conditions, such as saltwater or extreme temperatures, look for bearings designed to withstand these environments. Sealed bearings may offer better protection against contaminants.

- Quality Matters: Invest in high-quality bearings from reputable manufacturers. While cheaper options may save you money upfront, they can lead to costly repairs and unsafe situations later on.

- Consult the Manual: Your trailer’s owner manual can provide valuable information regarding the correct bearing size and specifications needed for your specific model.

Taking the time to choose the right trailer wheel bearings can significantly enhance your trailer's performance and longevity. Tow with peace of mind, knowing that trailerwatchdog is standing guard. Visit trailerwatchdog.com for more information on how our monitoring systems can help you maintain your trailer's safety.