Maintaining your trailer in top condition is vital for both safety and performance, and one of the most crucial components to monitor is the wheel bearing. Understanding the importance of wheel bearing inspection can save you from costly repairs and potential accidents on the road.

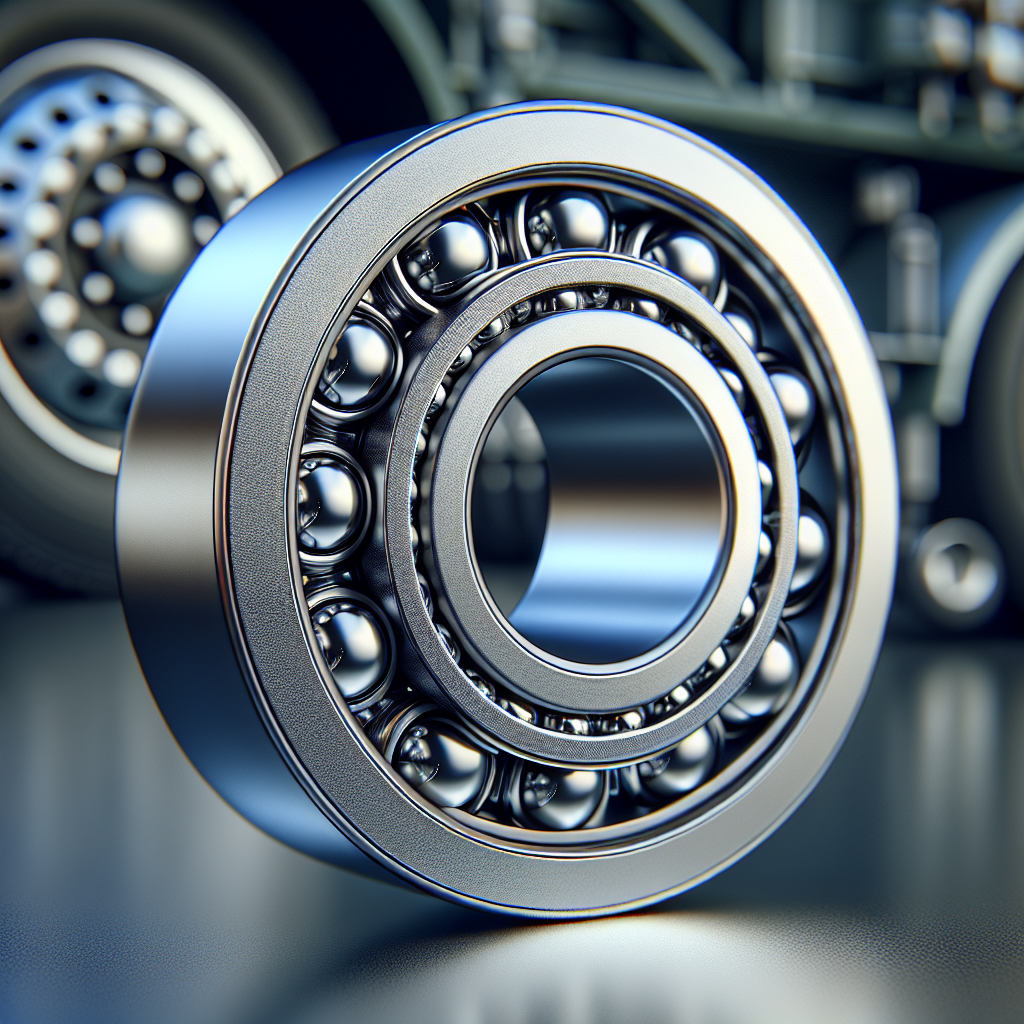

Wheel bearings play a key role in supporting the weight of the trailer and ensuring smooth rotation of the wheels. When they are in good condition, they minimize friction and help maintain stability. However, worn or damaged bearings can lead to severe consequences, including:

- Increased heat generation: As bearings wear out, friction increases, causing excessive heat that can lead to failure.

- Loss of control: Failing bearings can result in wheel lock-up or detachment, making it difficult to steer your trailer.

- Increased wear on tires: Poorly maintained bearings can cause uneven tire wear, which affects traction and safety.

Regular inspections allow you to catch issues early, ensuring that your trailer remains safe and functional. It's essential to check for signs of wear, such as noise, play in the wheel, or overheating during operation.

Tow with peace of mind, knowing that trailerwatchdog is standing guard. Our trailer monitoring system can provide real-time data that helps prevent catastrophic failures, allowing you to focus on your journey without worry.

Signs Indicating Your Trailer Needs Inspection

Recognizing the signs that indicate your trailer needs inspection is crucial for maintaining safety on the road. Ignoring these signals can lead to severe mechanical issues, increasing the risk of accidents or breakdowns. Here are some key indicators to watch for:

- Unusual Noises: If you hear grinding, rumbling, or whirring sounds coming from your trailer wheels, it could signify a problem with the wheel bearings. These noises often indicate that the bearings are worn out or damaged.

- Excessive Heat: After a journey, carefully check the temperature of the wheel hubs. If they feel excessively hot to the touch compared to the others, it's a sign that there may be an issue, such as insufficient lubrication or bearing failure.

- Vibration or Play: If you notice excessive vibration while towing or if you can feel play when you shake the wheel, this could indicate worn bearings. Such symptoms compromise handling and can lead to dangerous situations.

- Uneven Tire Wear: Inspect your trailer tires regularly. If they exhibit uneven wear patterns, it may be due to faulty wheel bearings affecting alignment and load distribution.

- Visual Inspection: Look for any visible damage or corrosion around the wheel hub and bearings. Signs of grease leaking out or discoloration can be a red flag.

Being vigilant about these signs and conducting regular inspections can help you catch issues before they escalate, ensuring a safer towing experience.

Step-by-Step Guide to Inspecting Wheel Bearings

Inspecting your trailer's wheel bearings is a vital process that can prevent costly repairs and enhance safety. Follow this step-by-step guide to effectively inspect your wheel bearings:

- Gather Necessary Tools: Before starting, ensure you have the right tools at hand, including a jack, jack stands, a wrench set, and a bearing packer. Having a clean work area is also essential.

- Lift the Trailer: Use the jack to lift the trailer and secure it on jack stands. This ensures safety while you work on the wheels.

- Remove the Wheel: Carefully detach the wheel by loosening the lug nuts with a wrench. Once removed, place the wheel aside in a safe spot.

- Inspect the Wheel Bearings: Remove the dust cap, if applicable, to expose the bearings. Check for any signs of wear, such as pitting or discoloration. Use your fingers to feel for smoothness; they should rotate freely without resistance.

- Clean the Bearings: If the bearings appear dirty, clean them using a degreaser and a soft cloth. It's essential to remove old grease before re-lubricating.

- Repack the Bearings: Apply new grease using a bearing packer or by hand, ensuring that the grease fills all cavities. This step is crucial for preventing premature wear.

- Reassemble the Wheel: Place the wheel back onto the hub, tighten the lug nuts by hand, and then securely tighten them in a crisscross pattern with the wrench.

- Lower the Trailer: Once everything is reassembled, carefully lower the trailer back to the ground.

Taking the time to follow this guide will help ensure that your trailer's wheel bearings are in optimal condition, providing a safer towing experience.

Tools Required for Effective Wheel Bearing Inspection

Having the right tools is essential for a thorough and effective wheel bearing inspection. Here’s a list of the necessary tools to ensure a smooth process:

- Jack and Jack Stands: A sturdy jack is critical for lifting the trailer, while jack stands provide additional safety and stability during inspection.

- Wrench Set: You’ll need a variety of wrenches to remove the lug nuts and other components of the wheel hub. A socket set can also be beneficial for easier access.

- Wheel Bearing Grease: Make sure to have high-quality grease on hand for repacking the bearings after inspection. This is crucial for maintaining their performance.

- Bearing Packer: This tool helps to apply grease evenly into the bearings, ensuring they are well-lubricated and reducing the risk of wear.

- Degreaser: A good degreaser will help clean the bearings and remove any old grease, dirt, or debris that could affect their function.

- Soft Cloths or Rags: You’ll need these to wipe down the bearings and surrounding areas during the cleaning process.

- Torque Wrench: This tool is vital for ensuring that the lug nuts are tightened to the manufacturer’s specifications, which is essential for safety on the road.

Equipping yourself with these tools not only simplifies the inspection process but also enhances your ability to maintain your trailer effectively. Regular checks can lead to improved performance and safety while towing.

Common Mistakes to Avoid During the Inspection

When conducting a wheel bearing inspection, avoiding common pitfalls can make a significant difference in both safety and performance. Here are some mistakes to steer clear of:

- Neglecting to Clean: Failing to clean the bearings and hub assembly before inspection can lead to inaccurate assessments. Dirt and old grease can hide potential issues.

- Inadequate Lubrication: Many individuals overlook the importance of proper lubrication. Insufficient grease can cause bearings to overheat and fail prematurely.

- Skipping the Torque Specifications: It’s vital to follow the manufacturer’s torque specifications for lug nuts. Over-tightening or under-tightening can cause wheel and bearing damage.

- Rushing the Inspection: Taking shortcuts can lead to missed signs of wear or damage. Make sure to dedicate enough time to thoroughly inspect each component.

- Ignoring Unusual Noises: If you hear grinding or squealing noises while driving, don’t dismiss them. These sounds are often early indicators of bearing issues that require immediate attention.

- Not Documenting Findings: Failing to keep a record of your inspections can lead to overlooking recurring issues. Documenting each inspection helps track performance over time.

By being mindful of these common mistakes, you can perform a more effective wheel bearing inspection, ensuring that your trailer remains safe and reliable on the road.

When to Seek Professional Help for Inspection

While many trailer owners can perform basic wheel bearing inspections, there are instances where seeking professional help is essential for ensuring safety and optimal performance. Here are some scenarios when it’s wise to consult a professional:

- Persistent Symptoms: If you notice ongoing issues such as noise, vibration, or heat emanating from the wheel area despite your inspections, it’s crucial to have a professional evaluate the situation.

- Complex Repairs Needed: Should your inspection reveal signs of significant wear, damage, or misalignment, it’s best to leave these repairs to experienced technicians who can ensure everything is correctly fixed.

- Lack of Experience: If you’re unsure about the inspection process or feel uncomfortable performing it, don’t hesitate to reach out to a professional. It’s better to be safe than sorry.

- Time Constraints: If you have a busy schedule that limits your ability to conduct thorough inspections, consider hiring a professional. They can save you time and provide peace of mind.

- After a Heavy Load or Long Trip: If you’ve recently towed a heavy load or driven long distances, it’s a good idea to have a professional inspect your trailer to identify any potential issues that may have arisen during the journey.

When in doubt, it’s always better to err on the side of caution. Tow with peace of mind, knowing that trailerwatchdog is standing guard. Our monitoring system provides crucial data to help you maintain your trailer's safety and performance.