Understanding the Importance of Trailer Wheel Bearings

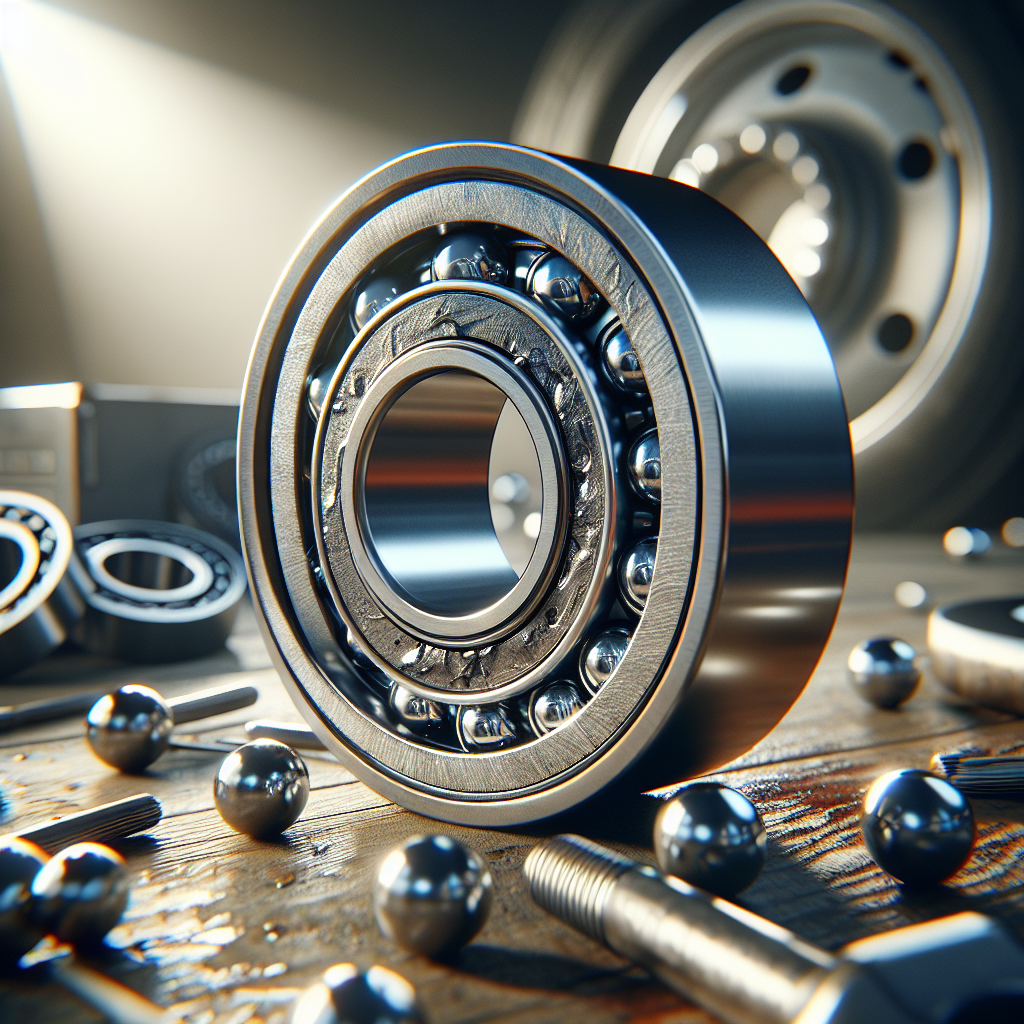

Trailer wheel bearings play a crucial role in the overall safety and functionality of your trailer. These small yet vital components allow the wheels to spin freely while supporting the weight of the trailer and its cargo. Neglecting the trailer wheel bearing inspection can lead to severe consequences, including unexpected breakdowns and costly repairs.

When wheel bearings deteriorate, they can cause:

- Excessive heat: Poorly lubricated or worn bearings generate heat, which can damage surrounding components and lead to failure.

- Increased wear: Failing bearings can lead to uneven tire wear, negatively impacting your trailer's performance and safety.

- Risk of accidents: If a wheel bearing completely fails while driving, it can result in a wheel detachment, posing a significant risk to both the trailer and other road users.

Regular inspection and maintenance of your trailer wheel bearings are essential to ensure they are functioning correctly. This includes checking for signs of wear, ensuring proper lubrication, and replacing bearings as needed. By prioritizing these safety measures, you can prevent catastrophic failures and enhance the longevity of your trailer.

To further enhance the safety of your towing experience, consider monitoring your trailer with advanced systems. Tow with peace of mind, knowing that trailerwatchdog is standing guard.

Signs Indicating Wheel Bearing Issues

Signs Indicating Wheel Bearing Issues

Recognizing the early signs of wheel bearing issues is essential for maintaining the safety and performance of your trailer. Ignoring these indicators can lead to more significant problems down the line. Here are some common signs to watch for:

- Unusual Noises: If you hear a grinding, humming, or rumbling noise coming from the wheel area, it may indicate that the bearings are worn or damaged. These sounds often become more pronounced as the trailer speeds up.

- Excessive Heat: If the wheel hub feels unusually hot to the touch after a drive, it could signal that the bearings are not adequately lubricated or are failing.

- Vibration or Wobbling: If you notice excessive vibration or wobbling in the trailer while towing, it may suggest that the bearings are not functioning correctly, potentially leading to wheel misalignment.

- Play or Movement: Check for any play in the wheel by grasping it at the 12 o'clock and 6 o'clock positions and trying to rock it back and forth. Any movement could indicate worn bearings.

- Uneven Tire Wear: If you observe uneven wear patterns on your tires, it could be a sign of bearing failure affecting the alignment and performance of the trailer.

Regularly monitoring your trailer for these signs can help you catch issues early, allowing for timely repairs and ensuring a safe towing experience.

Step-by-Step Trailer Wheel Bearing Inspection Process

Step-by-Step Trailer Wheel Bearing Inspection Process

Conducting a thorough trailer wheel bearing inspection is crucial for ensuring your trailer operates smoothly and safely. Follow this step-by-step process to effectively inspect your wheel bearings:

- Gather Your Tools: Before starting, ensure you have the necessary tools, including a jack, lug wrench, bearing grease, and a clean cloth.

- Lift the Trailer: Using a jack, lift the trailer until the wheel is off the ground. Secure the trailer with jack stands for safety.

- Remove the Wheel: Use a lug wrench to remove the lug nuts and take off the wheel. This will give you access to the hub and bearings.

- Inspect the Hub: Check for any signs of damage or excessive wear on the hub. Look for cracks, rust, or any irregularities.

- Check the Bearings: Remove the grease seal and take out the bearings. Inspect them for pitting, discoloration, or roughness. If any issues are found, it may be time for replacement.

- Clean and Lubricate: Clean the bearings with a suitable solvent to remove old grease. After cleaning, apply a liberal amount of fresh bearing grease before reassembling.

- Reassemble and Test: Reinstall the bearings and grease seal, put the wheel back on, and tighten the lug nuts. Lower the trailer and perform a test run to ensure everything is functioning correctly.

By following this inspection process, you can help prevent wheel bearing failures, ensuring safer travels on the road.

Tools Required for Effective Wheel Bearing Inspection

Tools Required for Effective Wheel Bearing Inspection

To perform a comprehensive trailer wheel bearing inspection, having the right tools on hand is essential. Each tool plays a vital role in ensuring that the inspection is thorough and efficient. Here’s a list of essential tools you will need:

- Jack: A reliable hydraulic or mechanical jack is necessary for lifting the trailer safely off the ground.

- Jack Stands: Always use jack stands to support the trailer once it’s lifted. This provides extra safety and stability while you work.

- Lug Wrench: A lug wrench is crucial for removing and tightening the lug nuts on your trailer's wheels.

- Grease Gun: For applying fresh grease to the wheel bearings, a grease gun ensures that the bearings are properly lubricated.

- Socket Set: A socket set allows you to easily remove any bolts or nuts that may be securing the wheel hub or other components.

- Cleaning Solvent: An appropriate cleaning solvent will help you clean the bearings and remove old grease effectively.

- Cloth or Rags: Use clean cloths or rags to wipe down parts and ensure no dirt or debris contaminates the bearings during reassembly.

- Safety Goggles: Protect your eyes while working by wearing safety goggles, especially when cleaning parts or working with tools.

Equipping yourself with these tools not only makes the inspection easier but also enhances safety, ensuring a smoother process when checking your trailer's wheel bearings.

Preventive Maintenance Tips for Trailer Wheel Bearings

Preventive Maintenance Tips for Trailer Wheel Bearings

Maintaining your trailer wheel bearings is crucial for ensuring safety and longevity. Regular preventive maintenance can help avoid catastrophic failures and costly repairs. Here are some effective tips to keep your trailer wheel bearings in top condition:

- Regular Inspections: Schedule routine checks, ideally every 12 months or after every 6,000 miles. Look for signs of wear, such as excessive play in the bearings or unusual noises while driving.

- Proper Lubrication: Ensure wheel bearings are adequately greased. Use high-quality grease that is suitable for your trailer's specific conditions. Re-grease bearings during inspections, particularly after long trips.

- Check for Overheating: Monitor axle temperatures during trips. An overheating bearing can indicate insufficient lubrication or damage. Consider using a temperature monitoring system for real-time data.

- Seal Integrity: Inspect the seals around the bearings regularly. Damaged or worn seals can allow dirt and moisture to enter, leading to corrosion and failure. Replace seals as needed.

- Tire Alignment: Ensure that tires are properly aligned and inflated. Misaligned or under-inflated tires can put extra stress on the wheel bearings, leading to premature wear.

- Store Properly: When not in use, store your trailer in a dry area to prevent rust and corrosion. Elevate the trailer off the ground if possible to relieve pressure on the wheel bearings.

Implementing these preventive maintenance tips will help extend the life of your trailer wheel bearings, ensuring a safer towing experience for you and your cargo.

When to Seek Professional Help for Wheel Bearing Issues

When to Seek Professional Help for Wheel Bearing Issues

While regular maintenance and inspections can help you identify and address minor issues with trailer wheel bearings, there are times when seeking professional help becomes essential. Here are some indicators that it’s time to consult a professional:

- Unusual Noises: If you hear grinding, humming, or clicking sounds coming from the wheel area, it may indicate that the wheel bearings are damaged or worn. Ignoring these sounds can lead to more severe problems.

- Excessive Heat: If you notice that the wheel hub is excessively hot to the touch during or after a trip, it could be a sign of overheating bearings. This condition can lead to failure if not addressed promptly.

- Vibration or Pulling: A trailer that pulls to one side or experiences unusual vibrations while towing may have bearing issues. This can compromise your control over the trailer, making it essential to seek professional assistance.

- Visual Damage: If you find visible signs of damage or wear during your inspections, such as pitting or rust on the bearings, it’s crucial to consult a professional for evaluation and replacement.

- Frequent Breakdown: If you consistently encounter issues with your trailer’s wheel bearings despite regular maintenance, a professional can help diagnose underlying problems that may not be apparent during self-inspections.

By recognizing these signs and seeking professional help when necessary, you can prevent further damage and ensure the safety of your trailer. Tow with peace of mind, knowing that trailerwatchdog is standing guard.