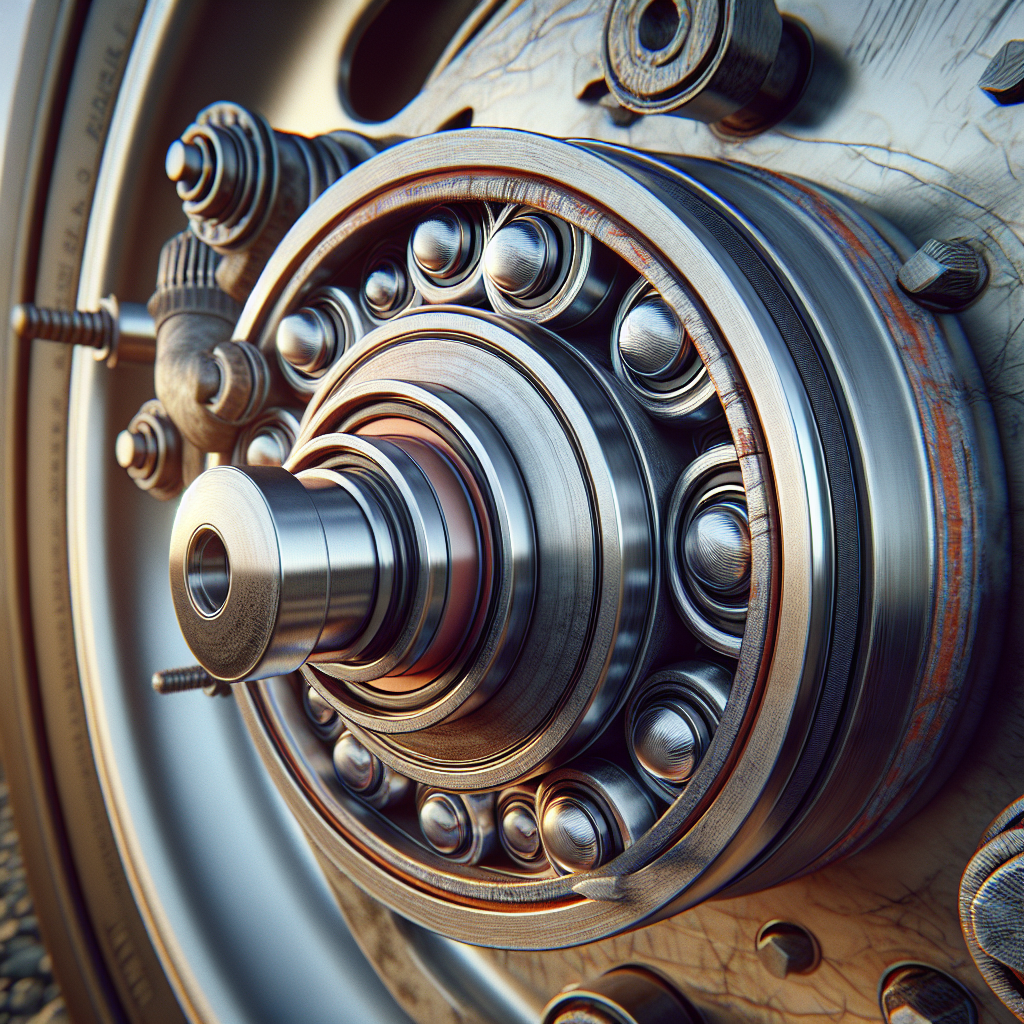

Understanding wheel bearings is crucial for anyone who operates a trailer. These small yet critical components play a significant role in ensuring the smooth operation of your trailer's wheels. Essentially, wheel bearings allow the wheels to rotate with minimal friction, which not only aids in the trailer's mobility but also enhances the overall safety of your towing experience.

When you consider the weight of the trailer and the loads it carries, the importance of wheel bearings becomes even more apparent. They bear the weight of the trailer and facilitate safe navigation over various terrains. Neglecting these components can lead to premature wear, which may result in catastrophic failures during transit.

Several factors affect the lifespan of wheel bearings, including:

- Driving conditions: Rough or uneven surfaces can accelerate wear.

- Load weight: Overloading the trailer can put excessive strain on the bearings.

- Maintenance practices: Regular inspections and lubrication can significantly extend their life.

Given their importance, it’s essential to monitor the condition of your wheel bearings regularly. This is where a smart trailer monitoring system like TrailerWatchdog comes into play. With our advanced technology, you can keep an eye on critical data that may indicate wear or overheating, ensuring that your trailer remains in optimal condition.

Tow with peace of mind, knowing that TrailerWatchdog is standing guard.

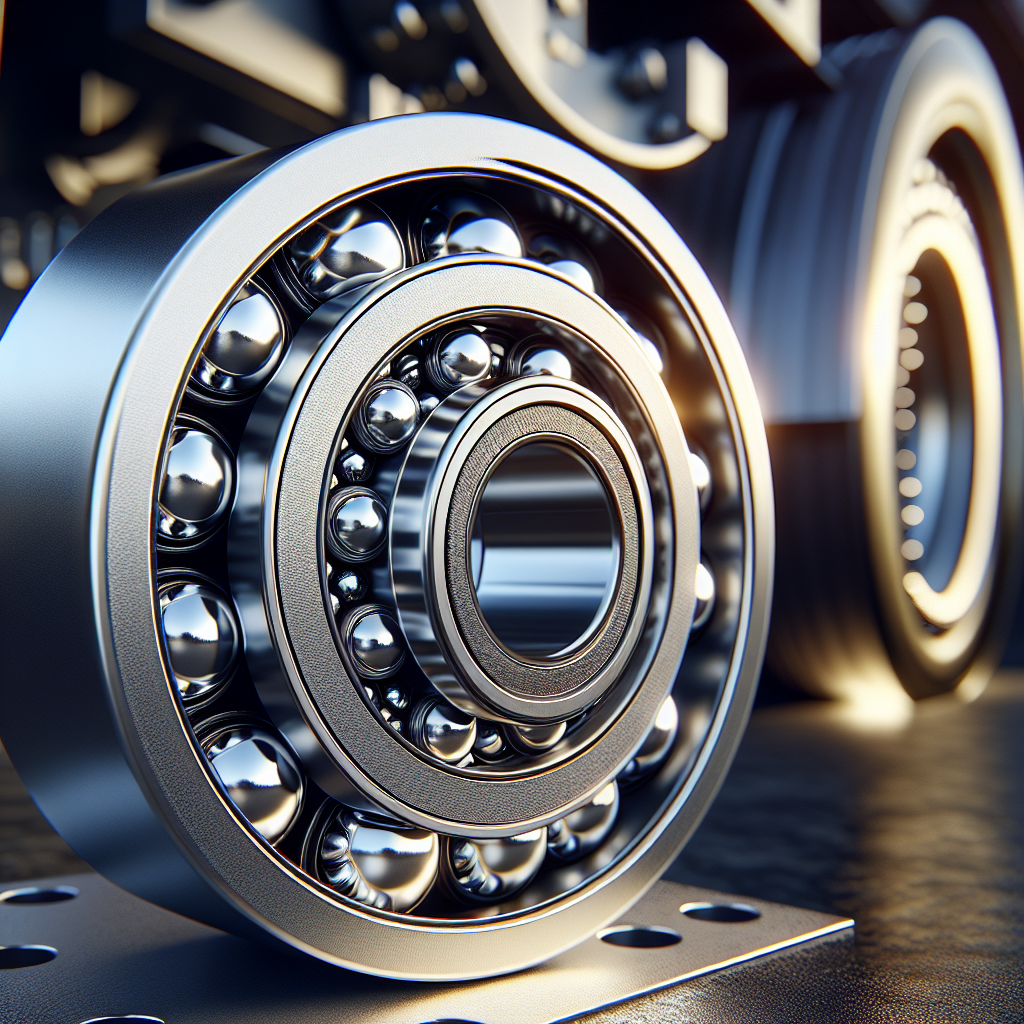

Typical Lifespan of Trailer Wheel Bearings

The typical lifespan of trailer wheel bearings can vary significantly depending on a number of factors. Generally, well-maintained wheel bearings can last anywhere from 10,000 to 100,000 miles. However, this range is not set in stone and can be influenced by multiple aspects of usage and maintenance.

Factors that may affect the lifespan of your trailer wheel bearings include:

- Quality of Bearings: Higher quality bearings are likely to endure longer under stress compared to cheaper alternatives.

- Usage Patterns: Frequent towing, particularly under heavy loads, can lead to quicker wear and tear.

- Environmental Conditions: Exposure to dirt, water, and other contaminants can cause corrosion and damage to bearings.

- Maintenance Frequency: Regular inspections and timely lubrication are essential for prolonging the life of your bearings.

Moreover, it's essential to monitor for signs of wear and tear, such as unusual noises, vibrations, or overheating. Addressing these issues early can make a significant difference in preventing more severe damage that could lead to costly repairs or even accidents.

Awareness of these factors will not only help you understand how long wheel bearings last on a trailer but also encourage proactive maintenance practices that can extend their lifespan.

Factors Influencing Wheel Bearing Longevity

Understanding the factors influencing wheel bearing longevity is crucial for trailer owners who want to ensure optimal performance and safety. Various elements can contribute to the wear and tear of wheel bearings, directly affecting their lifespan.

Here are some key factors to consider:

- Load Capacity: Exceeding the recommended weight limit for your trailer can place excessive strain on the wheel bearings, leading to premature failure.

- Road Conditions: Rough, unpaved, or uneven surfaces can increase the impact on wheel bearings, causing them to wear out more quickly than those used on smooth roads.

- Environmental Elements: Exposure to harsh weather conditions, such as extreme heat or cold, can lead to expansion and contraction of bearing materials, affecting their integrity. Additionally, exposure to saltwater or corrosive substances can cause rust and deterioration.

- Lubrication Maintenance: Proper lubrication is essential for reducing friction and heat buildup. Regularly checking and replacing the grease can significantly enhance bearing longevity.

- Installation Quality: The way wheel bearings are installed can also have a profound effect on their lifespan. Improper installation can lead to misalignment, increasing stress on the bearings.

By being aware of these factors, trailer owners can take proactive steps to maintain their wheel bearings, ensuring they last longer and perform safely throughout their lifespan.

Signs That Indicate Wheel Bearing Wear

Recognizing the signs that indicate wheel bearing wear is essential for maintaining the safety and reliability of your trailer. Early detection of problems can save you from catastrophic failures and costly repairs. Here are some warning signs to watch for:

- Unusual Noises: A common indication of wheel bearing wear is a grinding or humming noise coming from the wheel area while driving. This sound may become louder as the speed increases.

- Vibration: If you notice excessive vibration in the trailer while towing, this could suggest that the wheel bearings are failing. The vibrations may be felt in the steering wheel or the trailer itself.

- Uneven Tire Wear: Worn-out wheel bearings can cause the wheels to misalign, leading to uneven tire wear. Regularly checking your tires for signs of uneven wear can help you catch bearing issues early.

- Play in the Wheels: If you can wiggle the wheels side-to-side or up-and-down when the trailer is lifted, this may indicate that the wheel bearings are loose or damaged.

- Overheating: If you notice that your wheel hubs are excessively hot to the touch after driving, it may be a sign of bearing failure, possibly due to insufficient lubrication or excessive friction.

Being vigilant and aware of these signs can help you address any issues before they escalate, ensuring the continued performance and safety of your trailer.

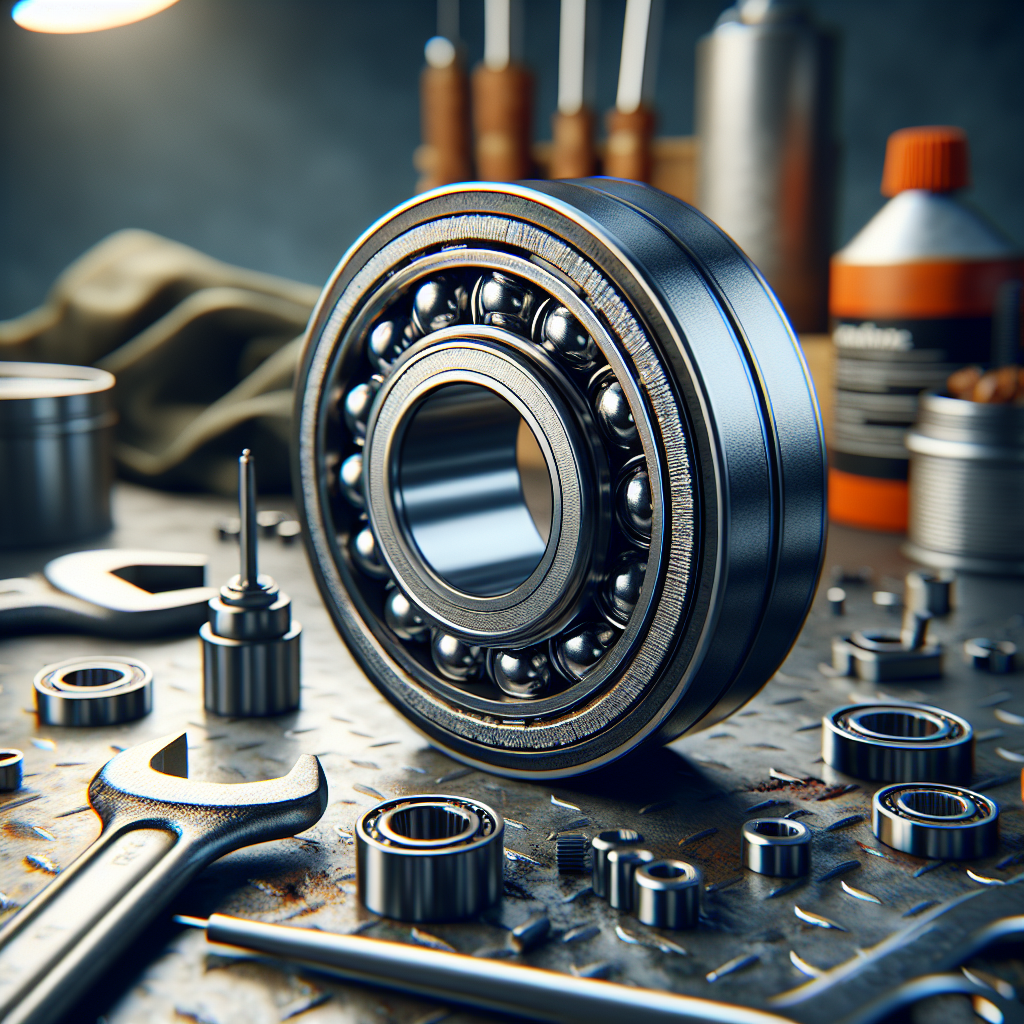

Maintenance Tips for Prolonging Wheel Bearings

To ensure the longevity of your trailer's wheel bearings, it is crucial to implement regular maintenance practices. By following these maintenance tips for prolonging wheel bearings, you can enhance their lifespan and avoid costly repairs:

- Regular Inspections: Schedule routine checks of your wheel bearings at least once a year or before long trips. Look for any signs of wear, damage, or excessive play in the bearings.

- Lubrication: Ensure that wheel bearings are adequately lubricated. Use high-quality grease and follow the manufacturer’s recommendations for the type and frequency of lubrication.

- Check for Proper Installation: Make sure that the wheel bearings are correctly installed. Improper installation can lead to premature failure, so consult a professional if you’re unsure.

- Monitor Load Capacity: Always adhere to the recommended load limits for your trailer. Overloading can place excessive stress on the wheel bearings, leading to faster wear and tear.

- Keep an Eye on Tire Pressure: Maintaining proper tire pressure can help reduce unnecessary strain on wheel bearings. Regularly check tire pressure and ensure it meets the manufacturer's specifications.

By incorporating these maintenance practices into your routine, you can significantly extend the life of your trailer's wheel bearings, thus enhancing overall safety and performance.

When to Replace Your Trailer Wheel Bearings

Understanding when to replace your trailer wheel bearings is essential for maintaining safety and performance. Over time, even the best-maintained wheel bearings will wear out due to factors such as heat, moisture, and road conditions. Here are some key indicators that it might be time for a replacement:

- Unusual Noises: Listen for grinding, squeaking, or rumbling sounds while driving. These noises often indicate that the bearings are failing and need immediate attention.

- Excessive Heat: If you notice that the wheel hub is excessively hot to the touch after a drive, this could signify that the bearings are not functioning properly and may require replacement.

- Visible Damage: Inspect the wheel bearings during routine checks. Look for signs of rust, pitting, or any physical damage that could compromise their integrity.

- Play in the Wheel: If there is noticeable play or wobbling in the wheel when it is lifted off the ground, it may be a sign that the bearings are worn out.

- Frequent Maintenance Issues: If you find yourself frequently needing to lubricate or adjust the bearings, this could indicate that they are reaching the end of their life cycle.

It is critical to address these signs promptly to avoid potential accidents or further damage. If you suspect your wheel bearings are failing, consult with a professional mechanic for a thorough inspection and replacement if necessary. Tow with peace of mind, knowing that trailerwatchdog is standing guard.