When it comes to the safe operation of your trailer, understanding the role of wheel bearings is essential. These critical components are designed to support the weight of the trailer while allowing the wheels to rotate smoothly. Properly functioning wheel bearings minimize friction, which is vital for safe towing and preventing breakdowns on the road.

Neglecting the condition of your wheel bearings can lead to serious issues, including:

- Increased Wear and Tear: Worn or damaged bearings can cause uneven tire wear, leading to costly replacements.

- Overheating: Insufficient lubrication can cause wheel bearings to overheat, which may result in catastrophic failure.

- Loss of Control: A failing wheel bearing can compromise your ability to steer, increasing the risk of accidents.

Regularly checking your wheel bearings can help you spot potential problems before they escalate into major failures. This proactive approach not only ensures the safety of your trailer but also enhances its overall performance and longevity.

If you want to take additional measures for safety, consider implementing a trailer monitoring system. Tow with peace of mind, knowing that trailerwatchdog is standing guard.

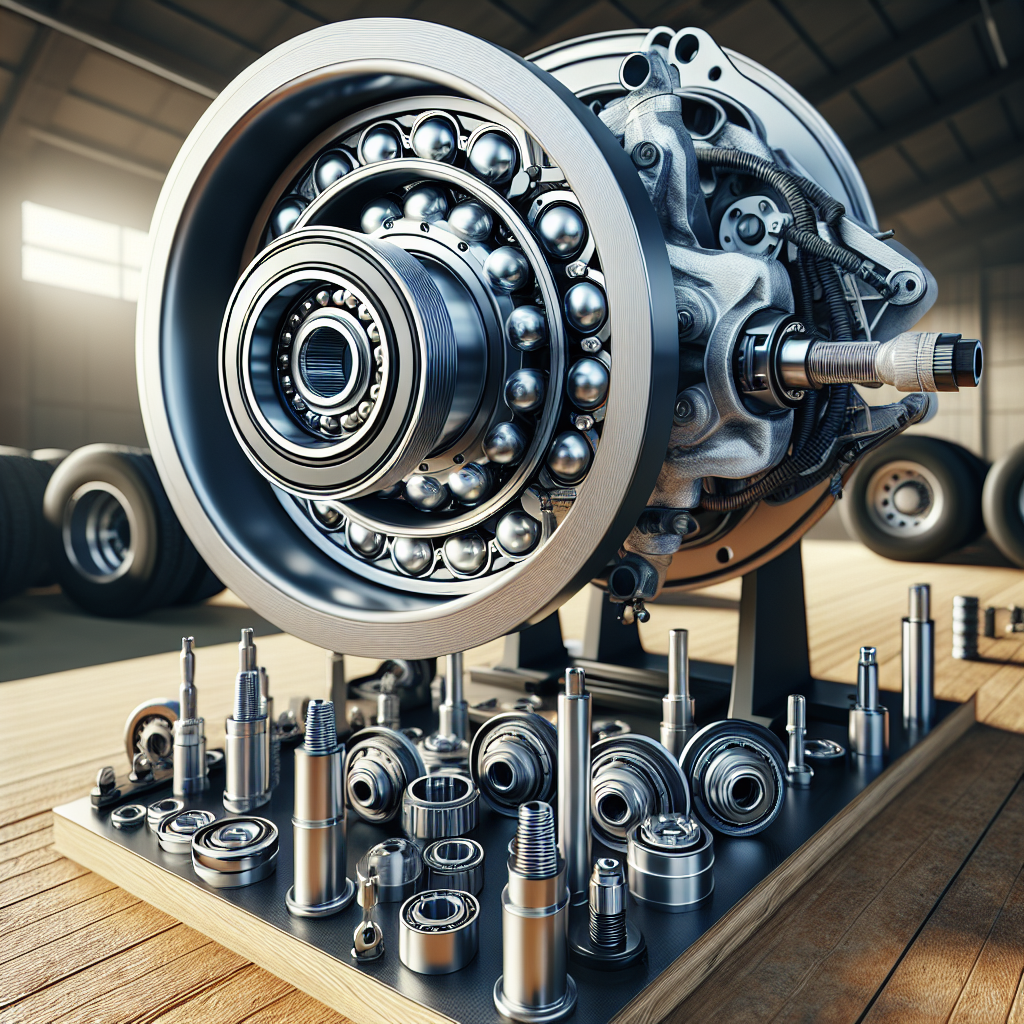

Tools Required for Checking Wheel Bearings

Before you embark on the task of checking wheel bearings, it's essential to gather the right tools. Having the appropriate equipment will not only make the process smoother but also ensure accurate results. Here’s a list of tools you will need:

- Jack: A reliable jack is necessary for lifting the trailer safely off the ground. Make sure it’s rated for the weight of your trailer.

- Jack Stands: Once the trailer is elevated, jack stands provide stability, preventing any accidental falls.

- Socket Set: A set of sockets will help you remove the wheel and access the hub assembly.

- Grease Gun: If you discover that your bearings are in good condition, a grease gun is vital for applying fresh lubricant.

- Digital Caliper: For precise measurements of the bearing and axle, a digital caliper can be invaluable.

- Cleaning Supplies: Brake cleaner and rags will help you clean the bearings and the surrounding area thoroughly.

- Safety Glasses and Gloves: Always prioritize safety by wearing protective gear while working on your trailer.

With these tools in hand, you'll be well-prepared to conduct a thorough inspection of your wheel bearings. This not only enhances your knowledge but also contributes to the overall safety of your trailer.

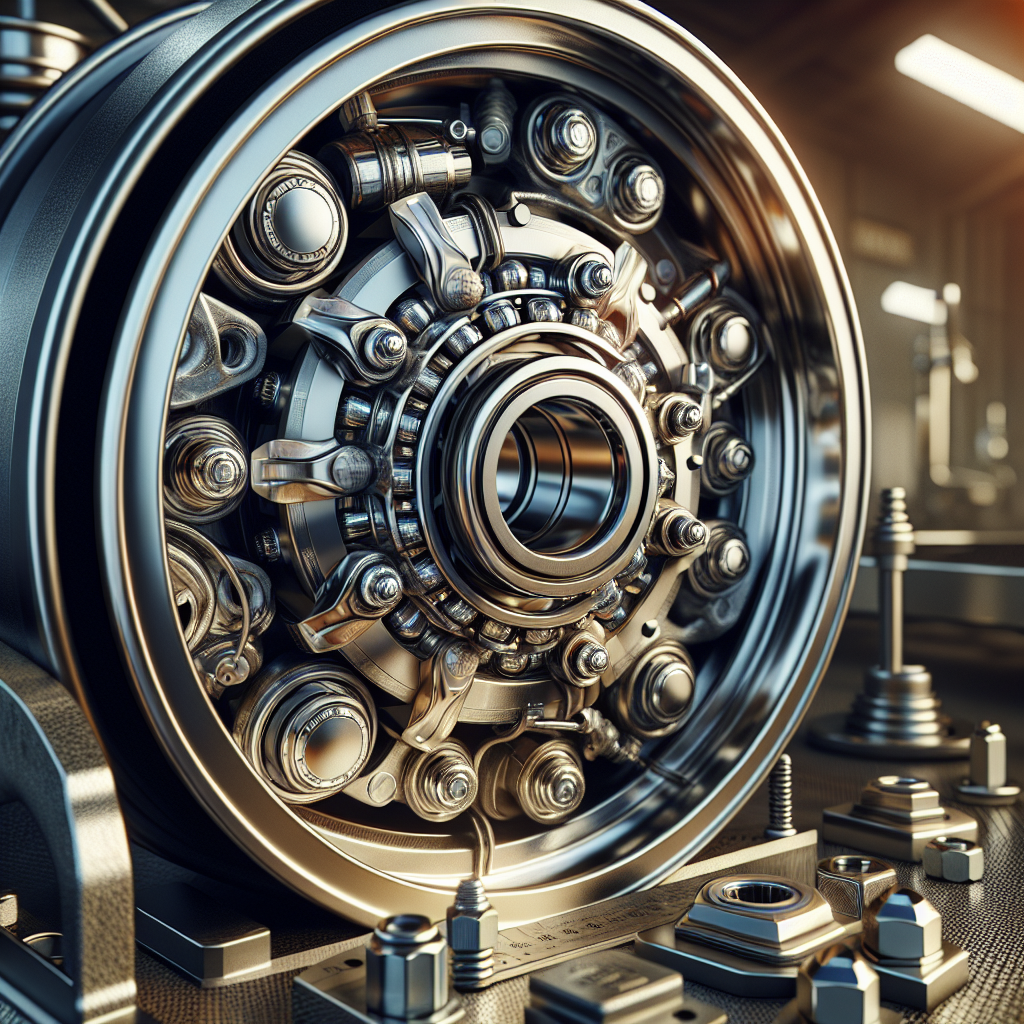

Step-by-Step Procedure for Checking Wheel Bearings

Once you have gathered the necessary tools, you can proceed with the step-by-step procedure for checking wheel bearings. This methodical approach ensures that you cover all aspects of the inspection, promoting safety and functionality.

Protect your trailer

- Prepare the Trailer: Park the trailer on a flat, stable surface. Engage the parking brake and ensure that the trailer is secure.

- Lift the Trailer: Use a jack to lift the trailer, then place jack stands underneath to provide additional support.

- Remove the Wheel: With your socket set, remove the lug nuts and take off the wheel to access the hub.

- Inspect the Bearing: Look for any signs of damage, such as pitting or discoloration, on the bearing surfaces. If the bearings appear worn or damaged, they will need to be replaced.

- Check for Play: With your hands, grasp the hub and try to wiggle it side to side. There should be minimal to no movement. Excessive play can indicate worn bearings or a faulty axle.

- Clean and Grease: If the bearings are in good shape, clean them thoroughly with brake cleaner. Use a grease gun to apply fresh grease to the bearings before reassembly.

- Reassemble: Carefully place the wheel back onto the hub and secure it with the lug nuts, tightening them in a star pattern to ensure even pressure.

- Lower the Trailer: Remove the jack stands and lower the trailer back to the ground.

Following this step-by-step guide will help ensure that your wheel bearings are in optimal condition, enhancing the performance and safety of your trailer.

Signs of Faulty Wheel Bearings to Watch For

Recognizing the signs of faulty wheel bearings is crucial for maintaining the safety and efficiency of your trailer. Ignoring these signs can lead to serious mechanical failures, costly repairs, and potential accidents. Here are some common indicators to watch for:

- Unusual Noises: A grinding, humming, or roaring sound while driving can indicate worn or damaged bearings. Pay close attention to any changes in noise that intensify when turning or accelerating.

- Wheel Play: If you notice excessive play or movement in the wheel when grasped, this may signify that the bearings are failing. Properly functioning bearings should hold the wheel securely with minimal movement.

- Vibration: A noticeable vibration in the trailer while towing can be a sign of bearing issues. This vibration may worsen with speed and can be felt through the towing vehicle.

- Heat Emission: Overheating of the wheel hub is another warning sign. If you touch the hub and it feels excessively hot, it could indicate that the bearings are not functioning properly.

- Tire Wear: Uneven or abnormal tire wear can also point to bearing problems. Inspect the tires for signs of wear patterns that could be associated with insufficient wheel alignment or faulty components.

Being vigilant about these signs can help you address potential issues before they escalate into significant problems. Regular checks and maintenance of your wheel bearings will enhance your trailer's overall performance and safety.

How to Maintain Trailer Wheel Bearings

Maintaining your trailer wheel bearings is essential for ensuring safe towing and prolonging the life of your trailer. Proper maintenance not only reduces the risk of failure but also enhances the overall performance of your vehicle. Here are some effective tips on how to maintain trailer wheel bearings:

- Regular Inspection: Conduct regular visual inspections of your wheel bearings. Look for signs of wear, rust, and damage. Check for any unusual noises during operation that could indicate bearing issues.

- Greasing: Ensure that your wheel bearings are properly greased. Depending on usage, trailer wheel bearings typically require greasing every 12 months or 12,000 miles. Use high-quality bearing grease that is suitable for your trailer type.

- Seal Checks: Inspect the grease seals for any signs of damage or wear. A damaged seal can allow moisture and dirt to infiltrate the bearings, leading to premature failure. Replace seals as needed to maintain optimal performance.

- Cleaning: When performing maintenance, it is crucial to clean the bearings thoroughly. Remove old grease and contaminants using a solvent or degreaser. Ensure the bearings are completely dry before applying fresh grease.

- Professional Servicing: If you're unsure about performing maintenance yourself, consider seeking professional help. A qualified technician can perform comprehensive inspections and servicing, ensuring your wheel bearings are in top condition.

By following these maintenance tips, you can help ensure that your trailer wheel bearings remain in good working order, contributing to a safer towing experience.

When to Seek Professional Help for Wheel Bearings

Understanding when to seek professional help for your trailer wheel bearings is crucial for maintaining safety and performance. While regular maintenance and inspections can be performed by most trailer owners, certain situations require the expertise of a trained technician. Here are some indicators that it’s time to consult a professional:

- Unusual Noises: If you hear grinding, squeaking, or rumbling noises coming from the wheel area, it may signal a serious issue with the wheel bearings. Ignoring these sounds can lead to catastrophic failure.

- Excessive Heat: If you notice that your wheel hubs are excessively hot to the touch after towing, this could indicate insufficient lubrication or bearing failure. A professional can diagnose and address the underlying issue.

- Visible Damage: Any signs of physical damage, such as cracks or chips in the bearings, should prompt immediate professional inspection. Damaged bearings can lead to significant safety hazards.

- Frequent Breakdowns: If you find yourself frequently experiencing trailer issues related to wheel bearings, it’s wise to seek professional assistance. Persistent problems may require a thorough inspection to identify and rectify the root cause.

- Uncertainty: If you are unsure about the condition of your wheel bearings or how to perform maintenance, it’s always better to err on the side of caution. A professional can provide peace of mind and ensure your trailer is safe for use.

When in doubt, don’t hesitate to reach out to a qualified technician for help. Regular maintenance and timely professional assessments can save you from costly repairs and ensure a safer towing experience. Tow with peace of mind, knowing that trailerwatchdog is standing guard.