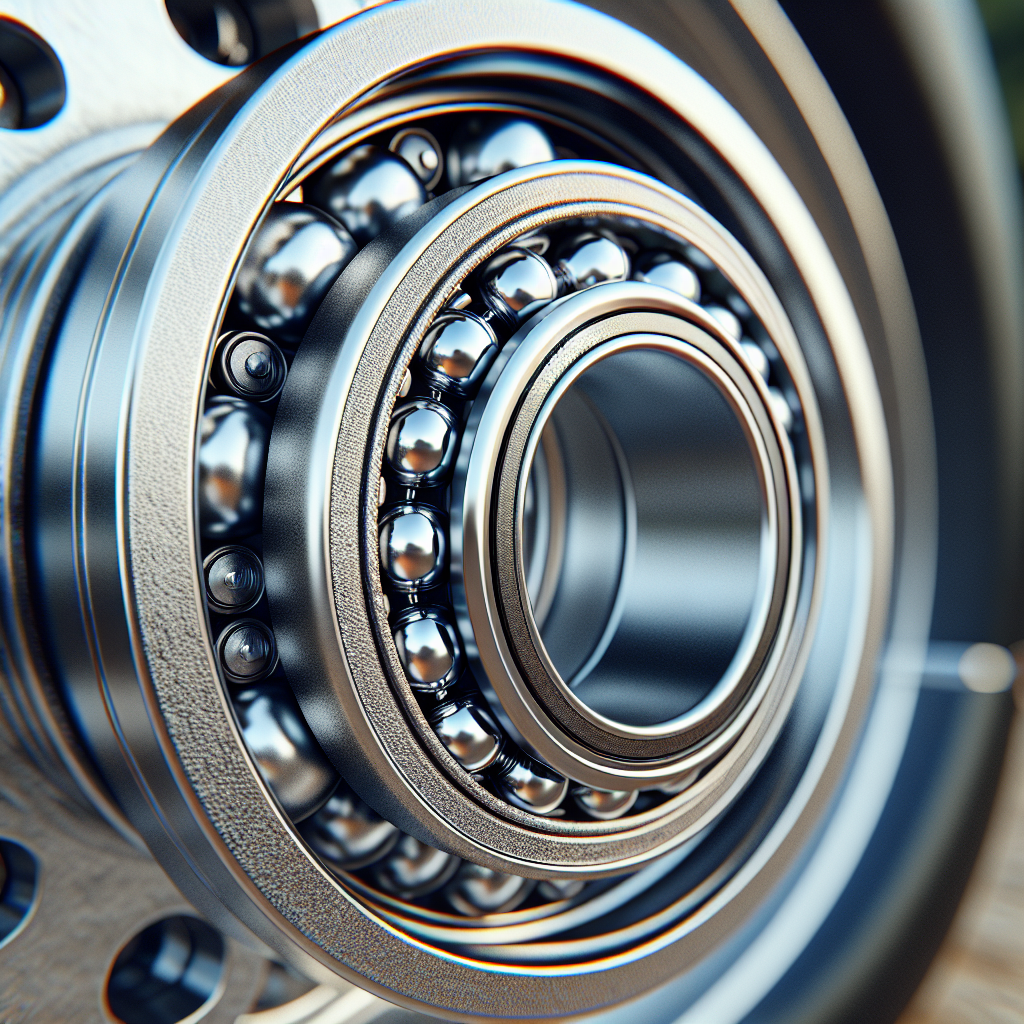

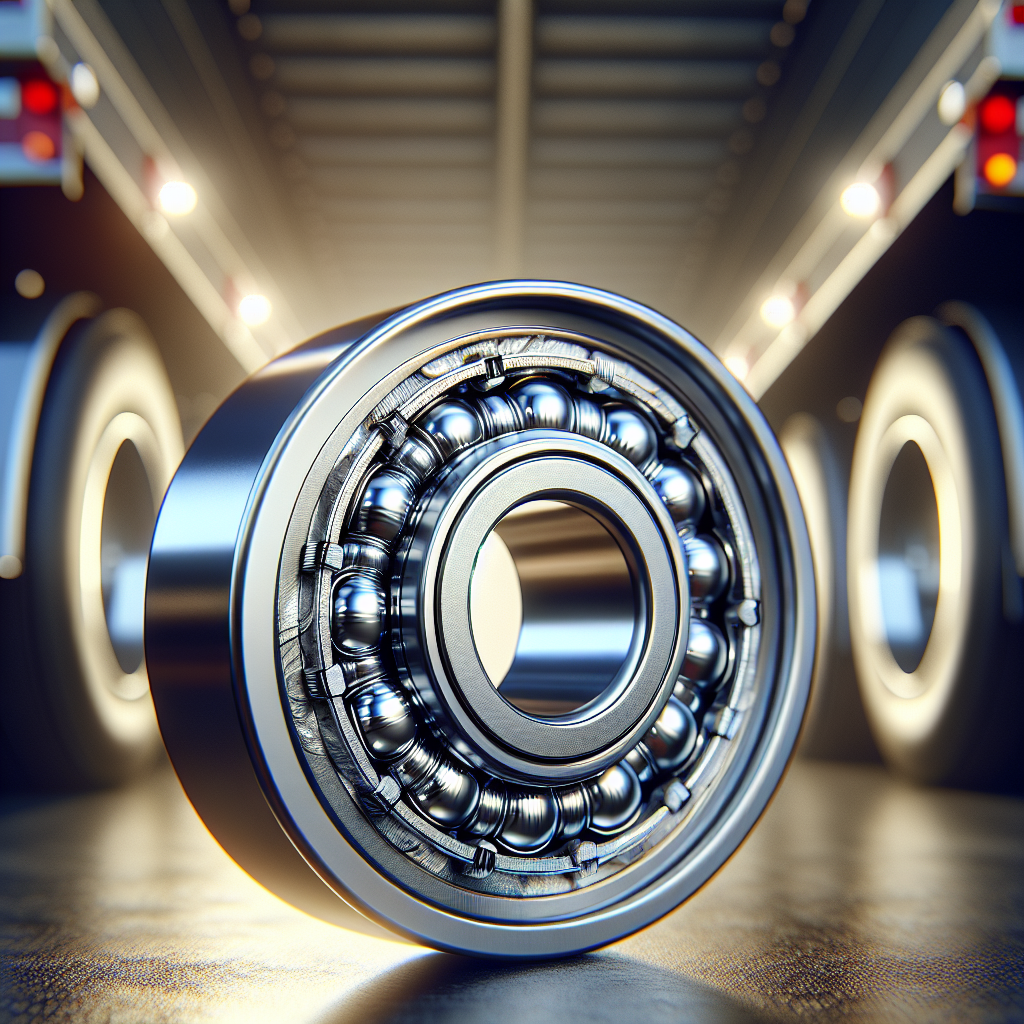

When it comes to trailer safety and performance, understanding the role of wheel bearings is critical. These components serve as the connection between the trailer wheels and the axle, enabling smooth rotation while supporting the weight of the trailer. Properly functioning wheel bearings are essential for maintaining stability, reducing wear and tear, and ensuring that the trailer operates efficiently.

Neglecting regular inspection and maintenance of wheel bearings can lead to significant issues, including:

- Overheating: Excessive friction can cause bearings to overheat, leading to premature failure.

- Increased Wear: Worn bearings can cause misalignment, resulting in uneven tire wear and reduced lifespan.

- Safety Hazards: A failure in the wheel bearing can result in a loss of control while towing, posing a serious safety risk.

For these reasons, it is vital to regularly check the condition of your trailer wheel bearings and address any signs of wear or damage promptly. Learning how to inspect trailer wheel bearings is an invaluable skill for any trailer owner. By recognizing the importance of these components, you can take proactive measures to ensure the longevity and safety of your trailer.

Tow with peace of mind, knowing that trailerwatchdog is standing guard.

Essential Tools for Bearing Inspection

Equipping yourself with the right tools is essential for effectively inspecting trailer wheel bearings. Having the necessary equipment not only simplifies the process but also enhances the accuracy of your inspection. Here are some vital tools you'll need:

- Socket Set: A complete socket set is crucial for removing the wheel hub and accessing the bearings.

- Grease Gun: This tool is essential for applying grease to the bearings, ensuring they remain lubricated during operation.

- Tire Pressure Gauge: Maintaining proper tire pressure helps reduce stress on the wheel bearings and can be checked easily with this tool.

- Magnifying Glass: For a closer inspection, a magnifying glass can help identify cracks or wear in the bearings that might not be visible to the naked eye.

- Cleaning Supplies: Items like rags, brushes, and solvent are important for cleaning the bearings and the hub before reinstallation.

Using these tools will allow you to perform a thorough inspection, identifying potential issues before they escalate into more significant problems. Each tool plays a pivotal role in ensuring that your bearings function optimally, contributing to the overall safety and performance of your trailer.

Step-by-Step Trailer Bearing Inspection Process

Performing a thorough inspection of your trailer wheel bearings is a critical step in maintaining your trailer's safety and performance. Follow this step-by-step process to ensure your bearings are in good condition:

- Prepare Your Workspace: Park your trailer on a flat surface and engage the parking brake. Gather all necessary tools and equipment before you begin.

- Remove the Wheel: Use your socket set to loosen and remove the lug nuts. Carefully take off the wheel to expose the hub assembly.

- Inspect the Hub Assembly: Check the hub for any signs of damage or wear. Look for rust, cracks, or any irregularities that could indicate a problem.

- Remove the Bearings: Carefully take out the bearings from the hub. Pay attention to how they are positioned for reassembly later.

- Examine the Bearings: Inspect each bearing for pitting, discoloration, or excessive wear. Spin the bearings to check for smoothness; any grinding or roughness is a sign they need replacing.

- Clean the Components: Use your cleaning supplies to thoroughly clean the bearings and the inside of the hub. Remove all old grease and debris.

- Repack the Bearings: Using the grease gun, repack the bearings with fresh grease, making sure to fill all cavities.

- Reassemble the Hub: Place the bearings back into the hub in the same orientation as before and reattach the wheel.

- Test the Wheel: Spin the wheel to ensure it rotates freely and smoothly. Check for any unusual noises or resistance.

By following this systematic approach, you can ensure that your trailer bearings are properly inspected and maintained, reducing the risk of catastrophic failure during travel.

Signs of Worn or Damaged Bearings

Understanding the signs of worn or damaged trailer bearings is essential for maintaining the safety and longevity of your trailer. Regular observation and awareness can prevent severe issues that may arise from neglect. Here are the key indicators to watch for:

- Excessive Heat: If you notice that the wheel hub is unusually hot to the touch after a drive, this could indicate that the bearings are failing. Overheating is often due to inadequate lubrication or excessive friction.

- Unusual Noises: Listen for grinding, squeaking, or rumbling sounds coming from the wheels while driving. These noises can suggest that the bearings are worn down and need immediate attention.

- Vibration: If you feel a noticeable vibration through the trailer or towing vehicle while driving, it may be a sign of uneven wear in the bearings or misalignment, which can lead to further complications.

- Play in the Wheel: If you can move the wheel side to side while the trailer is stationary, this indicates that the bearings may be loose or worn and need to be adjusted or replaced.

- Visual Signs: Inspect the bearings for any signs of rust, corrosion, or discoloration. These visual cues can indicate that the bearings are deteriorating and may need to be serviced soon.

By being vigilant and recognizing these signs early on, you can address bearing issues before they escalate, ensuring a safer towing experience.

Maintenance Tips for Trailer Wheel Bearings

Proper maintenance of your trailer wheel bearings is crucial for ensuring their longevity and optimal performance. Here are some essential maintenance tips for trailer wheel bearings that every trailer owner should follow:

- Regular Inspection: Conduct routine checks to identify any signs of wear, damage, or overheating. Inspect the bearings at least once a season or before long trips to ensure they are in good condition.

- Proper Greasing: Ensure that your bearings are adequately lubricated. Use high-quality grease designed for trailer bearings and follow the manufacturer’s recommendations for greasing intervals.

- Check for Play: Periodically check for any play in the wheel by grasping it at the top and bottom and attempting to rock it. If there’s movement, the bearings may need adjustment or replacement.

- Seal Inspection: Inspect the seals for any signs of wear or damage. Seals protect the bearings from dirt and debris, and compromised seals can lead to bearing failure.

- Wheel Hub Cleaning: Keep the wheel hubs clean and free from dirt and debris. A clean environment helps prevent contamination of the bearings and extends their lifespan.

- Monitor Tire Pressure: Maintain proper tire pressure as it can affect the load distribution on the bearings. Under-inflated or over-inflated tires can lead to premature bearing wear.

By following these maintenance tips, you can ensure that your trailer wheel bearings remain in optimal condition, enhancing your safety on the road.

When to Seek Professional Help for Bearings

While routine maintenance and inspections can often help you keep your trailer wheel bearings in check, there are situations where it’s best to seek professional help for bearings. Recognizing these scenarios can save you from potential accidents and costly repairs. Here are some signs that indicate it’s time to consult a professional:

- Excessive Noise: If you hear grinding, humming, or squeaking noises coming from the wheel area, it could be a sign of bearing failure. Don’t ignore these sounds; they often indicate that the bearings need immediate attention.

- Overheating: If the wheel hubs feel excessively hot to the touch, it may indicate that the bearings are not properly lubricated or are damaged. This situation requires professional evaluation to prevent further damage.

- Visible Damage: If you notice any visible wear, cracks, or chips in the bearings or seals, it’s essential to have them inspected by a professional to determine if they need replacement.

- Frequent Adjustments: If you find yourself frequently adjusting or replacing bearings, it may be time to consult a professional to identify underlying issues that could be causing these problems.

- Suspension Issues: If you experience any unusual handling or suspension issues while towing your trailer, it may be related to the bearings. A professional can diagnose the problem and provide the necessary repairs.

Don’t take chances with your safety. If you observe any of these signs, it’s crucial to seek expert help to ensure your trailer is roadworthy. Tow with peace of mind, knowing that trailerwatchdog is standing guard.