When it comes to maintaining your trailer, understanding the importance of wheel bearings is crucial. Wheel bearings play a vital role in ensuring that the wheels of your trailer rotate smoothly, providing stability and safety while on the road. They are designed to support the weight of the trailer, allowing for efficient movement of the wheels.

Neglecting the condition of your trailer wheel bearings can lead to serious issues, including:

- Overheating: Excessive heat can cause the bearings to wear out prematurely, leading to potential failure.

- Increased friction: Poorly lubricated bearings can create unnecessary friction, which not only affects performance but can also increase fuel consumption.

- Traction loss: Failing bearings can compromise the connection between the wheels and the trailer, leading to instability and poor handling.

Regularly performing a trailer wheel bearing check can help you catch any issues before they escalate into more significant problems. This proactive approach will not only enhance the lifespan of your trailer but also ensure a safer towing experience.

Tow with peace of mind, knowing that trailerwatchdog is standing guard.

Signs Indicating Wheel Bearing Issues

Recognizing the early signs of wheel bearing issues is essential for preventing catastrophic failures. Here are some common indicators that may suggest your trailer's wheel bearings are not functioning optimally:

- Unusual Noises: If you hear a grinding, humming, or growling sound while towing, it could indicate that the bearings are worn or damaged. Pay attention to any noise that increases with speed.

- Excessive Play: When you grasp the wheel and notice significant movement or play, it could mean that the bearings are loose or failing. This can affect the stability and handling of your trailer.

- Overheating: If you notice that the wheel hub feels unusually hot to the touch during or after towing, it may indicate that the bearings are not properly lubricated or are failing.

- Vibration: A noticeable vibration while towing can be a sign of an issue with the wheel bearings. This vibration can lead to further damage if not addressed promptly.

- Tire Wear: Uneven or excessive tire wear can also be a symptom of wheel bearing problems. Inspect your tires regularly to catch any unusual wear patterns early.

Being aware of these signs can help you maintain your trailer's performance and safety. Regular checks and maintenance are key to ensuring that your wheel bearings remain in good condition.

Step-by-Step Guide to Check Wheel Bearings

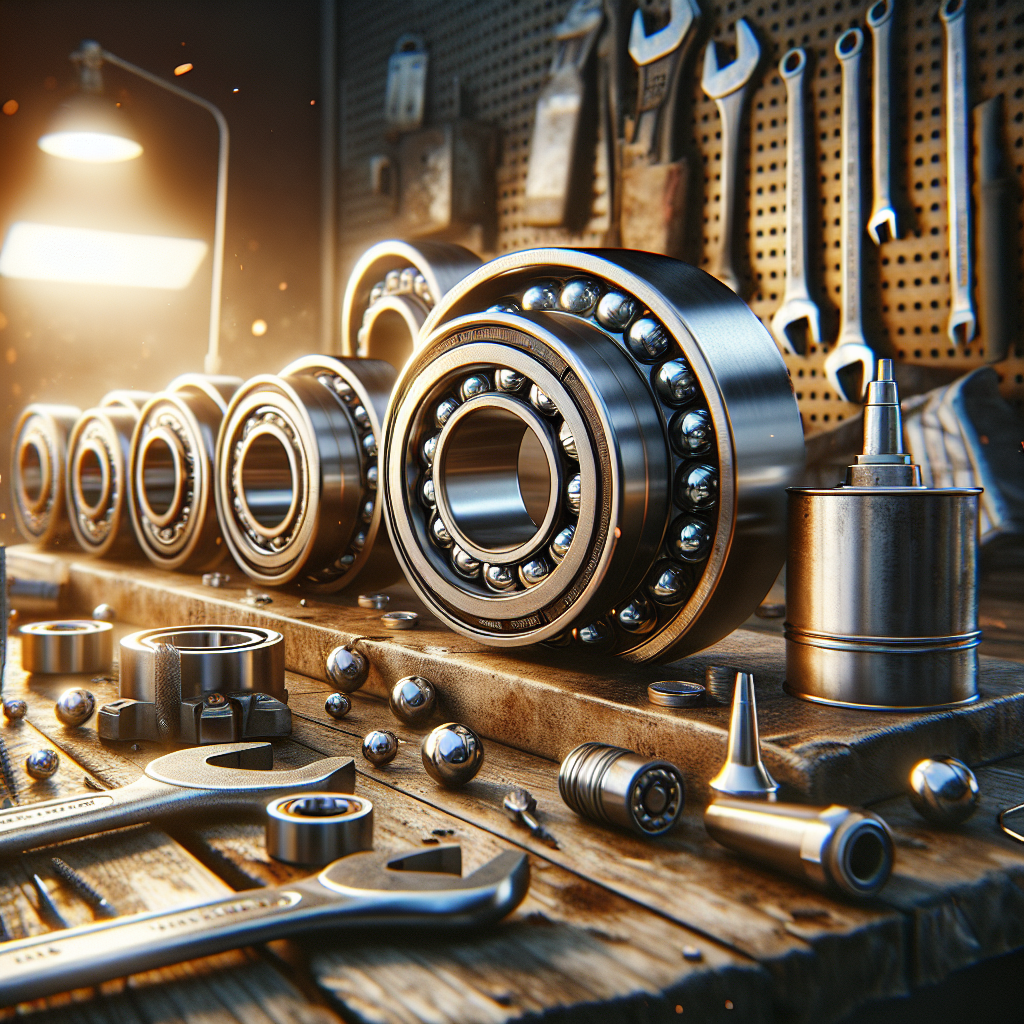

Performing a trailer wheel bearing check is a straightforward process that can save you from costly repairs down the line. Follow this step-by-step guide to ensure your wheel bearings are in good condition:

- Gather Your Tools: You will need a jack, jack stands, a lug wrench, wheel bearing grease, and a bearing packer if necessary. Make sure to have clean rags on hand for any debris.

- Lift the Trailer: Use the jack to lift the trailer off the ground. Secure it with jack stands to ensure safety while you work.

- Remove the Wheel: Use the lug wrench to remove the lug nuts and take off the wheel. This will give you access to the hub and bearings.

- Inspect the Bearings: Carefully remove the dust cap and cotter pin, if present. Take out the inner and outer bearings and inspect them for any signs of wear, rust, or damage. Clean them thoroughly with a rag.

- Check the Races: Examine the bearing races in the hub for any grooves or scoring. These imperfections can lead to premature bearing failure.

- Grease the Bearings: If the bearings are in good condition, pack them with high-quality wheel bearing grease. Ensure they are completely coated to prevent moisture and debris from entering.

- Reassemble: Place the bearings back into the hub, reinsert the dust cap, and secure everything with the cotter pin. Reattach the wheel and tighten the lug nuts to the manufacturer's specifications.

- Lower the Trailer: Carefully remove the jack stands and lower the trailer back to the ground.

Following these steps will help ensure that your trailer's wheel bearings are functioning properly, enhancing safety and performance on the road.

Tools Needed for Trailer Wheel Bearing Check

Before embarking on a trailer wheel bearing check, it’s essential to gather the right tools to make the process efficient and effective. Below is a list of the necessary tools:

- Jack: A reliable hydraulic or scissor jack is crucial for lifting your trailer off the ground safely. Ensure it has a weight rating that suits your trailer’s load.

- Jack Stands: Always use jack stands in conjunction with your jack to provide additional safety while you work under the trailer.

- Lug Wrench: This tool is necessary for loosening and tightening the lug nuts on your trailer wheels. A cross wrench or a torque wrench can provide better leverage.

- Bearing Grease: High-quality wheel bearing grease is essential for lubricating the bearings and preventing wear and tear. Look for grease specifically designed for wheel bearings.

- Bearing Packer: If available, a bearing packer can make the process of greasing your bearings cleaner and more efficient by evenly distributing grease.

- Rags or Paper Towels: These are necessary for cleaning any dirt or debris from the bearings and hub during the inspection process.

- Cotter Pins: If your trailer's bearings use cotter pins, have some spares on hand for reassembly.

- Torque Wrench: This tool is important for ensuring the lug nuts are tightened to the manufacturer’s specifications, preventing them from loosening during travel.

Having these tools ready will not only streamline your trailer wheel bearing check but will also enhance your safety and efficiency throughout the process.

Preventive Maintenance for Trailer Bearings

Preventive maintenance for trailer bearings is crucial in ensuring the longevity and reliability of your trailer. Routine checks and maintenance can help identify potential problems before they escalate into significant issues. Here are some key preventive measures to consider:

- Regular Inspections: Schedule regular inspections of the wheel bearings, ideally every 12 months or after a specific mileage. This includes checking for any signs of wear, damage, or excessive play.

- Greasing Bearings: Ensure that your wheel bearings are adequately greased. Depending on usage, you may need to repack the bearings every 5,000 to 10,000 miles. Always use the correct type of grease recommended by the manufacturer.

- Monitor Temperature: Keeping an eye on axle temperature can help detect overheating, which may indicate a problem with the bearings. Consider using a trailer monitoring system that provides real-time axle temperature data.

- Check Seals: Inspect the bearing seals for any signs of damage or wear. Damaged seals can allow moisture and dirt into the bearing assembly, leading to premature failure.

- Proper Loading: Adhere to the manufacturer's weight limits to avoid putting undue stress on the bearings. Overloading can lead to overheating and bearing failure.

- Wheel Alignment: Ensure your trailer is properly aligned. Misalignment can cause uneven wear on bearings and tires, leading to costly repairs.

By implementing a robust preventive maintenance routine, you can ensure that your trailer bearings remain in excellent condition, reducing the risk of catastrophic failures and enhancing your towing experience.

When to Seek Professional Help for Bearings

Knowing when to seek professional help for your trailer bearings can save you from costly repairs and ensure your safety on the road. While routine checks and preventive maintenance are essential, there are specific signs that indicate professional intervention is necessary:

- Unusual Noises: If you hear grinding, squeaking, or a rumbling sound coming from the wheel area, it’s a clear sign that something is wrong. These noises often indicate bearing wear or damage that needs immediate attention.

- Excessive Heat: If you notice that the wheel hub is unusually hot to the touch after a trip, this may signal overheating bearings. Professional help is essential to diagnose the issue accurately and prevent further damage.

- Visible Damage: Inspecting your bearings regularly may reveal visible signs of wear, such as rust or pitting. If you observe any significant damage, it’s advisable to consult a professional.

- Frequent Adjustments: If you find yourself adjusting the bearings repeatedly or they seem to require constant maintenance, this could indicate a deeper problem that needs expert analysis.

- Vibration Issues: Unusual vibrations while towing can signal misalignment or failing bearings. A professional can determine the root cause and recommend appropriate fixes.

Seeking professional help can provide peace of mind and ensure that your trailer is safe for use. Don’t hesitate to reach out to an expert if you notice any of these warning signs. Tow with peace of mind, knowing that trailerwatchdog is standing guard.