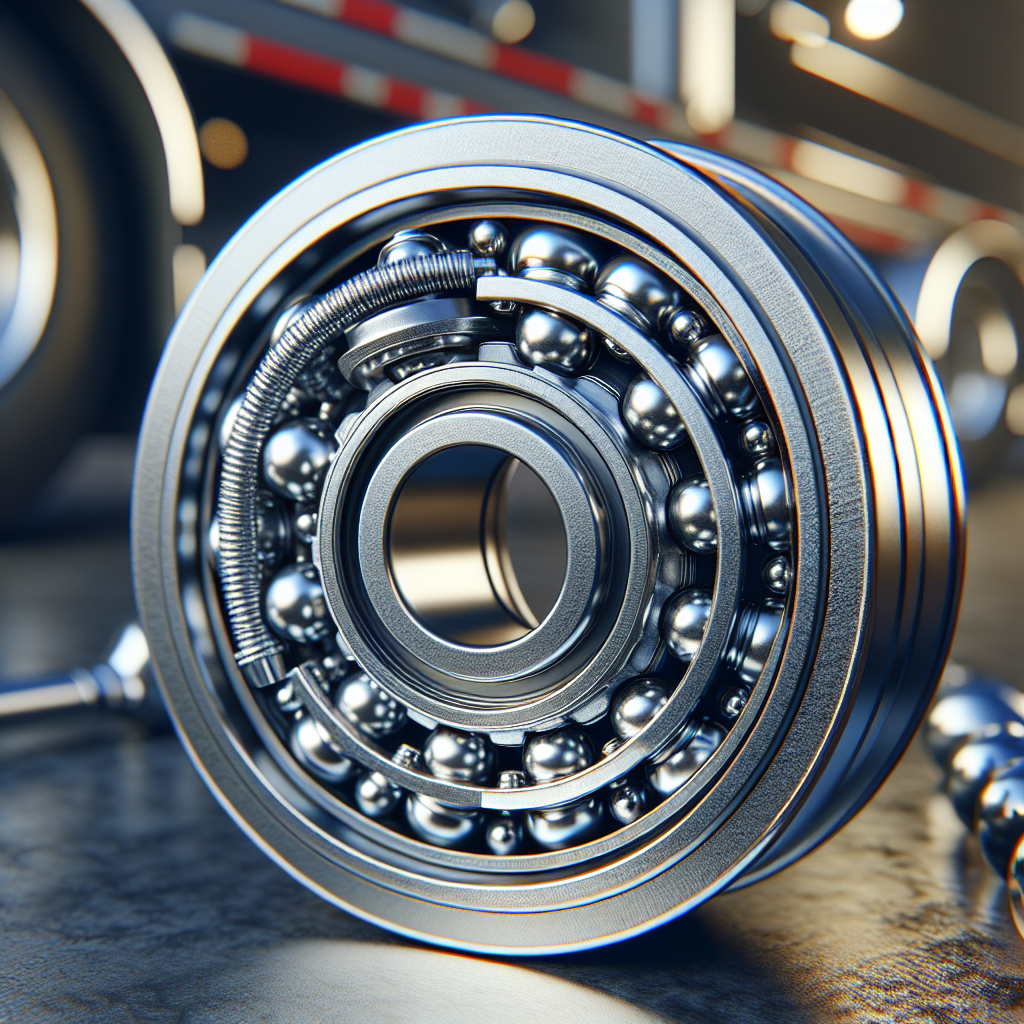

When it comes to maintaining your trailer, understanding the role of wheel bearings is crucial for ensuring both safety and performance. These small yet vital components allow the wheels to rotate smoothly while supporting the weight of the trailer. If the wheel bearings are loose or damaged, it can lead to a series of problems that can compromise your towing experience.

A trailer wheel bearing loose can cause excessive play in the wheel, which results in uneven wear of the tires and could lead to tire blowouts. Furthermore, a compromised bearing can generate excessive heat, putting additional strain on the braking system and leading to potential brake failure. This scenario not only poses a risk to the trailer but also to other motorists on the road.

Regular inspections of wheel bearings can help identify issues before they escalate. Look for signs like:

- Unusual noises: A grinding or humming sound while driving may indicate bearing wear.

- Excessive wheel movement: Any noticeable play when shaking the wheel could suggest loose bearings.

- Overheating: Check for excessive heat on the wheel hub after a drive, which can indicate bearing issues.

By being proactive in checking your wheel bearings, you can prevent costly repairs and ensure a safer towing experience. Tow with peace of mind, knowing that trailerwatchdog is standing guard. Visit trailerwatchdog.com for a reliable trailer monitoring system that keeps you informed about your trailer's condition.

Signs Indicating a Loose Wheel Bearing

Recognizing the signs of a loose wheel bearing is essential for maintaining the safety and functionality of your trailer. Ignoring these indicators can lead to severe complications, including accidents and costly repairs. Here are some common signs that your trailer wheel bearing is loose:

- Noise: One of the first signs of a loose bearing is unusual noise. You may hear a grinding, rumbling, or humming sound emanating from the wheels while driving. This noise typically increases with speed and may become more pronounced when turning.

- Vibration: If you feel significant vibrations in the steering wheel or the trailer itself, it could be due to a loose wheel bearing. This vibration is often noticeable at various speeds and can indicate that the wheel is not spinning correctly.

- Heat: After a drive, carefully check the wheel hubs for excessive heat. A loose bearing can create friction, leading to a hot hub. If one wheel is noticeably hotter than the others, it’s a strong indicator of a problem.

- Play in the Wheel: You can perform a simple test by shaking the wheel back and forth. If there is noticeable play or movement, this can indicate that the bearings are loose and need immediate attention.

- Tire Wear: Uneven or excessive tire wear can also signal a loose bearing. If the tires are wearing down more on one side than the other, it may be time to inspect the wheel bearings.

Being aware of these signs can help you take timely action before a loose wheel bearing leads to more significant issues, ensuring a safer towing experience.

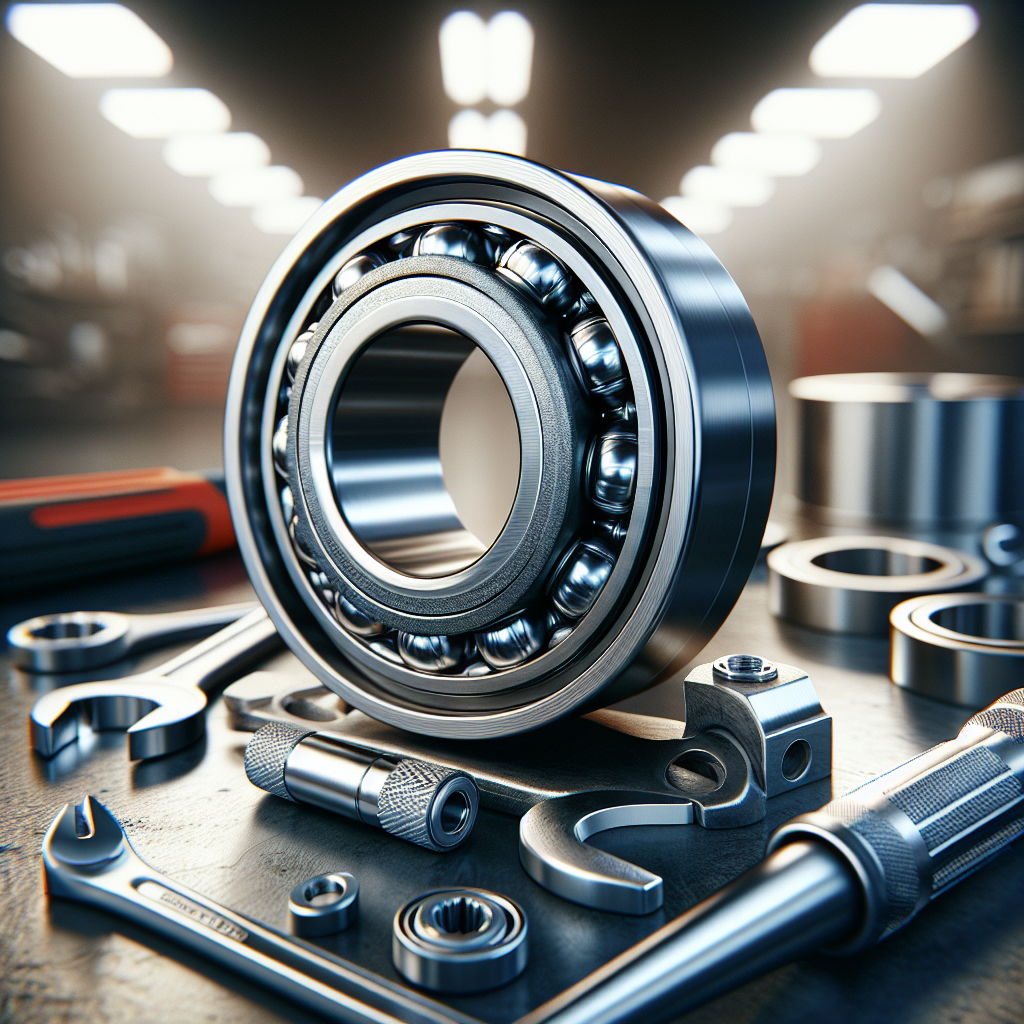

How to Check Your Trailer Wheel Bearing

Checking your trailer wheel bearing is a straightforward process that can prevent potential disasters on the road. Regular inspections will help ensure that your bearings are functioning correctly and that your trailer remains safe for towing. Here’s a step-by-step guide on how to effectively check your trailer wheel bearing:

- Gather Necessary Tools: Before you begin, make sure you have the right tools on hand. You will need a jack, jack stands, a lug wrench, and possibly a torque wrench.

- Lift the Trailer: Use the jack to lift the trailer. Ensure that it is adequately supported by jack stands to prevent any accidents while you work.

- Remove the Wheel: Using the lug wrench, loosen and remove the lug nuts. Carefully take off the wheel to expose the hub and the bearings.

- Inspect the Bearings: Look closely at the bearings for any signs of wear or damage. Check for discoloration, pitting, or excessive grease buildup. If the bearings appear damaged, they may need to be replaced.

- Check for Play: Grasp the hub and try to move it back and forth. If you feel any play or movement, this indicates that the wheel bearing may be loose and requires adjustment or replacement.

- Reassemble: If everything appears in good condition, reattach the wheel, ensuring that the lug nuts are properly torqued according to the manufacturer’s specifications.

Performing these checks regularly can help maintain your trailer’s performance and safety. If you're unsure about the condition of your wheel bearings, consider consulting a professional.

Consequences of Ignoring Loose Wheel Bearings

Ignoring a loose trailer wheel bearing can lead to serious consequences that may jeopardize both your safety and the longevity of your trailer. Understanding these risks is crucial for any trailer owner who prioritizes safe towing and reliable performance. Here are some potential consequences:

- Increased Wear and Tear: A loose wheel bearing can cause uneven wear on tires and other components of the trailer. This can lead to premature tire replacement and increased maintenance costs.

- Overheating: When wheel bearings are not properly secured, they can generate excessive heat due to friction. Overheating can lead to bearing failure, which might result in a complete breakdown while on the road.

- Loss of Control: A loose bearing can cause the wheel to wobble, making it difficult to maintain control of the trailer. This instability can increase the risk of accidents, especially during high-speed travel or sharp turns.

- Damage to the Axle: If left unchecked, a loose wheel bearing can cause damage to the axle itself. This can lead to costly repairs and even necessitate the replacement of the entire axle assembly.

- Increased Risk of Accidents: Ultimately, the most severe consequence of ignoring a loose wheel bearing is the heightened risk of accidents. A wheel that detaches at high speed can have devastating effects, not only for the trailer owner but also for other road users.

To avoid these serious risks, it is essential to regularly inspect your trailer and address any signs of looseness in the wheel bearings promptly. Taking preventive measures can save you time, money, and ensure the safety of everyone on the road.

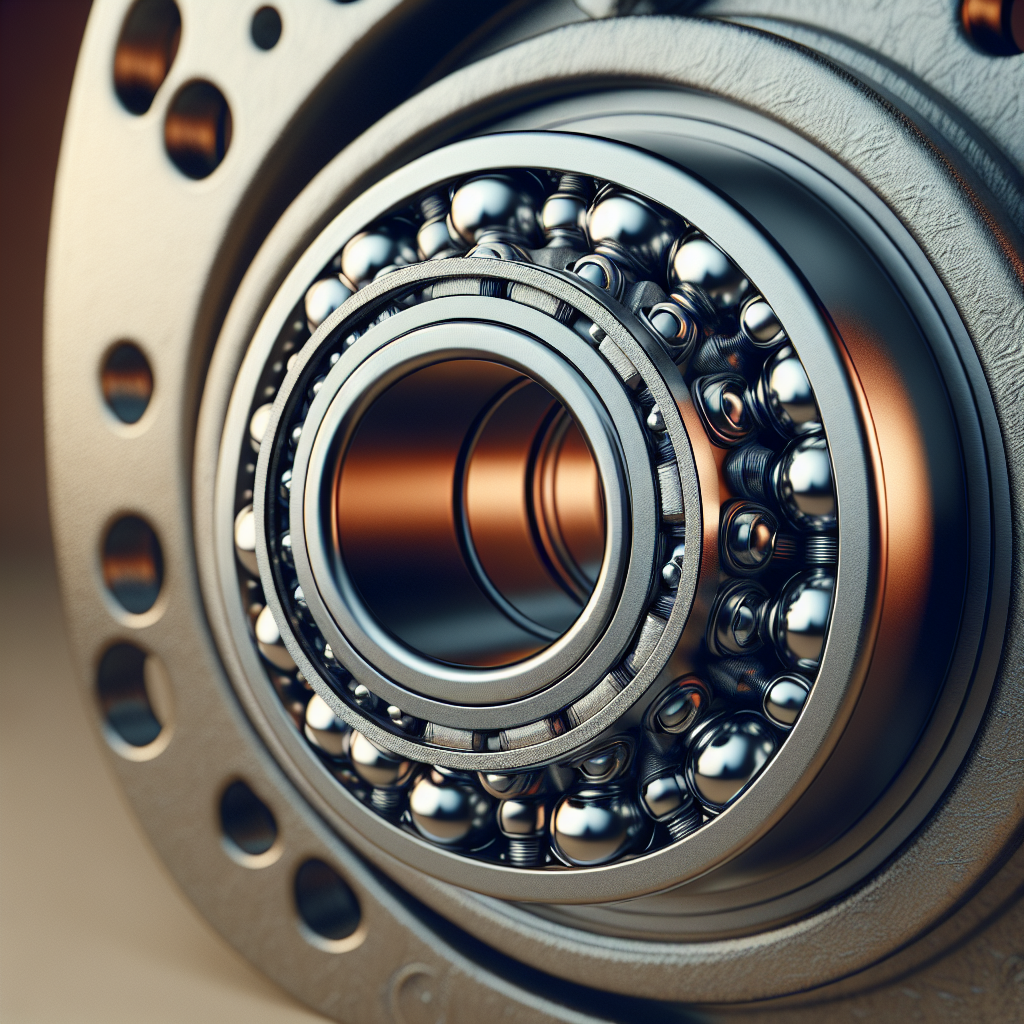

Preventive Maintenance for Trailer Wheel Bearings

Implementing a routine of preventive maintenance for your trailer wheel bearings is essential in ensuring safe and efficient towing. By taking proactive steps, you can significantly reduce the risk of bearing failure and extend the life of your trailer. Here are some effective maintenance practices:

- Regular Inspections: Conduct visual inspections of the wheel bearings during each trailer use. Look for signs of grease leaks, discoloration, or any unusual noises when the wheels are spun. Early detection can prevent larger issues down the road.

- Greasing Schedule: Ensure that your wheel bearings are properly greased according to the manufacturer's recommendations. Over time, grease can break down or become contaminated, which reduces its effectiveness.

- Tightening and Adjustments: Check the tightness of the wheel bearings as part of your regular maintenance routine. Loose bearings can lead to excessive play and wear, so it’s important to adjust them as needed to keep them secure.

- Temperature Monitoring: Consider using a trailer monitoring system that provides real-time data on axle temperature. An increase in temperature can indicate potential bearing issues, allowing for timely intervention.

- Professional Servicing: Schedule professional inspections and maintenance periodically. Experienced technicians can provide thorough checks and perform necessary repairs that may be overlooked during regular inspections.

By adhering to these preventive maintenance practices, you can ensure that your trailer remains in optimal condition, minimizing the risk of a loose wheel bearing and enhancing the overall safety of your towing experience.

When to Seek Professional Help for Wheel Bearings

While routine maintenance and inspections can greatly reduce the likelihood of issues with your trailer wheel bearings, there are times when professional assistance is crucial. Recognizing the right moments to seek expert help can save you from potential accidents and costly repairs. Here are some indicators that it’s time to consult a professional:

- Unusual Noises: If you start hearing grinding, humming, or clicking sounds coming from the wheels, this could indicate that the bearings are worn out or damaged. Ignoring these sounds can lead to more significant problems.

- Excessive Heat: If you notice that the wheel hub is excessively hot to the touch during or after towing, this could be a sign of bearing failure. A professional can help diagnose the issue and prevent further damage.

- Play in the Wheel: If you feel play or wobbling in the wheel when you shake it, this is a clear indication that the wheel bearing is loose or failing. A technician should evaluate the situation immediately.

- Frequent Adjustments Required: If you find yourself constantly adjusting the wheel bearings, it may indicate that they are beyond repair and need replacement.

- Inadequate Maintenance Knowledge: If you're unsure about how to properly maintain or inspect your trailer wheel bearings, seeking help from professionals ensures that your trailer remains safe and roadworthy.

Don’t wait until a small issue escalates into a major problem. Taking proactive measures by consulting with experts can enhance the safety of your towing experience. Tow with peace of mind, knowing that trailerwatchdog is standing guard.