When it comes to maintaining your trailer, understanding how to properly remove wheel bearings is crucial. Wheel bearings play a vital role in ensuring the smooth operation of your trailer's wheels, allowing for safe and efficient towing. Regular maintenance, including the removal and inspection of these components, can prevent costly repairs and enhance overall performance.

In this guide, we will delve into how to take wheel bearing off your trailer with clear, step-by-step instructions. We will cover the necessary tools, safety precautions, and best practices to ensure that the process is both straightforward and effective.

Before you begin, it's essential to have a solid understanding of the components involved. Wheel bearings are typically located within the wheel hub assembly, secured by a variety of retaining devices. Removing them requires careful attention to detail and a methodical approach to avoid damaging any parts.

As you prepare to embark on this maintenance task, remember that proper monitoring of your trailer's health is equally important. Tow with peace of mind, knowing that trailerwatchdog is standing guard. Our unique trailer monitoring system provides critical axle temperature and tire data to help prevent catastrophic failures. Let’s ensure your trailer is both safe and reliable!

Essential Tools for Wheel Bearing Extraction

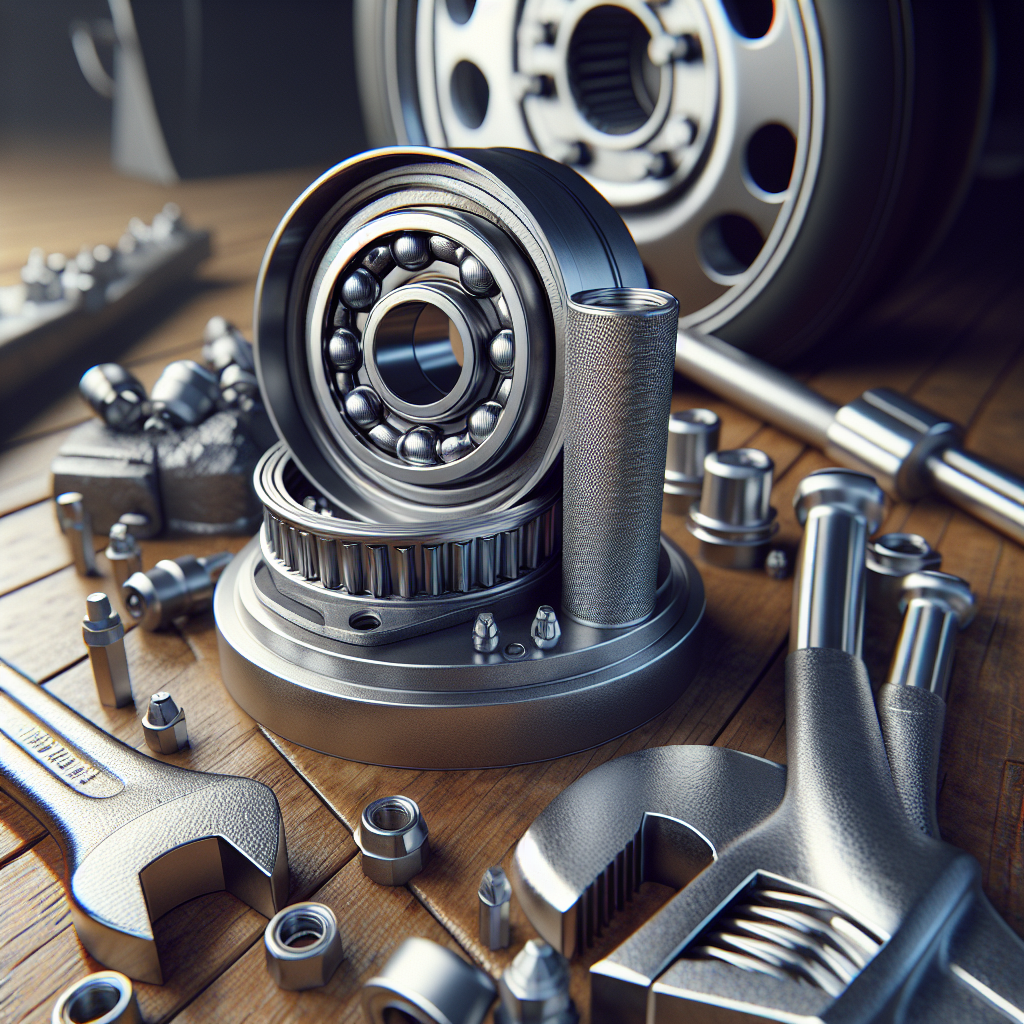

Equipping yourself with the right tools is essential for successfully removing wheel bearings from your trailer. Having the necessary equipment not only streamlines the process but also ensures that you can perform the task safely and effectively. Here’s a list of essential tools you’ll need:

- Socket Set: A variety of sockets will help you remove the wheel hub assembly and other components that secure the bearings.

- Wrench Set: Wrenches are crucial for loosening and tightening bolts, especially in tight spaces.

- Hammer: A rubber mallet can be used to gently tap components loose without causing damage.

- Bearing Puller: This tool is specifically designed to extract the bearings from the wheel hub, ensuring they come out smoothly.

- Grease: For reinstallation, having high-quality grease will ensure the longevity and proper functioning of your new bearings.

- Safety Gear: Always wear safety glasses and gloves to protect yourself while working on your trailer.

Using the correct tools will not only make the removal process more efficient but also help prevent any accidental damage to your trailer components. Ensure you have all these tools at hand before you start the extraction process, as this preparation will set the stage for a successful maintenance task.

Step-by-Step Process for Taking Off Wheel Bearings

Removing wheel bearings from your trailer may seem daunting, but by following a step-by-step process, you can accomplish this task with ease. Below is a comprehensive guide to help you through the removal:

- Prepare Your Workspace: Ensure you have a clean and organized area to work on your trailer. Gather all necessary tools and safety gear.

- Lift the Trailer: Use a hydraulic jack to lift the trailer and secure it on jack stands. Make sure it is stable before proceeding.

- Remove the Wheel: Use your socket set to detach the lug nuts and take off the wheel. This will expose the brake drum or rotor.

- Detach the Brake Components: If your trailer has brakes, carefully remove the brake drum or rotor. Ensure you keep track of any hardware or components you remove.

- Access the Wheel Hub: Once the brakes are out of the way, you’ll have access to the wheel hub where the bearings are located.

- Use a Bearing Puller: Attach your bearing puller to the wheel hub and carefully extract the bearings. Make sure to apply even pressure to avoid damaging the hub.

- Inspect and Clean: After removal, inspect the bearings and the hub for any signs of wear or damage. Clean the area thoroughly to prepare for new bearings.

Following these steps will help ensure a smooth and safe removal of your trailer’s wheel bearings. Always proceed with caution and consult your trailer’s manual for specific instructions related to your model.

Common Mistakes to Avoid During Removal

When it comes to removing wheel bearings from your trailer, avoiding common mistakes can save you time, money, and potential safety hazards. Here are some pitfalls to watch out for:

- Skipping Safety Gear: Always wear appropriate safety gear, such as gloves and goggles. Neglecting safety precautions can lead to injuries during the removal process.

- Forgetting to Support the Trailer: Failing to securely lift and support the trailer with jack stands can be dangerous. Always ensure the trailer is stable before working underneath it.

- Not Taking Pictures: Before disassembling any components, take photos of the setup. This can serve as a reference for reassembly, helping you avoid confusion later.

- Using the Wrong Tools: Ensure you have the correct tools for the job, such as a bearing puller. Using inappropriate tools can damage the bearings or the hub.

- Forcing Components Apart: If you encounter resistance when removing bearings, avoid using excessive force. Forcing components can lead to damage. Instead, double-check the process and ensure all fasteners are removed.

- Neglecting to Clean: After removing the bearings, it’s crucial to clean the hub and surrounding areas. Failing to do so can lead to contamination when installing new bearings.

By being aware of these common mistakes, you can ensure a smoother and more efficient wheel bearing removal process, ultimately enhancing the longevity and safety of your trailer.

Tips for Maintaining Trailer Wheel Bearings

Maintaining your trailer's wheel bearings is essential for ensuring smooth operation and preventing costly repairs. Here are some valuable tips to help you keep your wheel bearings in optimal condition:

- Regular Inspections: Schedule regular inspections of your wheel bearings. Look for signs of wear, such as unusual noises or excessive heat during operation. Early detection can prevent major issues down the road.

- Proper Lubrication: Ensure that your wheel bearings are properly lubricated. Use high-quality grease specifically designed for trailer bearings and follow the manufacturer's recommendations on frequency and amount.

- Seal Integrity: Check the integrity of the bearing seals regularly. Damaged or worn seals can allow moisture and dirt to enter, leading to premature bearing failure. Replace seals as needed to maintain a tight seal.

- Tire Maintenance: Keep an eye on your trailer tires. Proper inflation and alignment can help reduce the load on the wheel bearings, extending their lifespan. Rotate tires regularly to ensure even wear.

- Storage Conditions: Store your trailer in a dry, sheltered location to prevent moisture damage. If possible, keep the trailer off the ground on blocks to reduce pressure on the bearings.

- Monitor Axle Temperature: Consider investing in a trailer monitoring system that provides real-time data on axle temperature. Anomalies in temperature can indicate issues with the bearings before they lead to failure.

By incorporating these maintenance tips into your routine, you can significantly extend the life of your trailer's wheel bearings and ensure safer towing experiences.

When to Seek Professional Help for Trailer Bearings

While many trailer maintenance tasks can be handled by DIY enthusiasts, there are certain situations where seeking professional help for your trailer bearings is crucial. Understanding when to call in the experts can save you time, money, and ensure your safety on the road.

- Unusual Noises: If you hear grinding, squealing, or clunking noises coming from the wheel area, it may indicate that the bearings are failing. Ignoring these sounds can lead to catastrophic failures.

- Excessive Heat: If you notice that the wheel hubs are excessively hot to the touch after a drive, this could be a sign of insufficient lubrication or bearing damage. A professional can diagnose and resolve the issue effectively.

- Visible Damage: If you observe any physical damage to the bearings, seals, or other related components, it’s best to consult a professional. They have the tools and expertise to assess the extent of the damage.

- Difficulty in Removal: If you’re struggling to remove the wheel bearings yourself, it may be a sign of corrosion or improper installation. A professional can handle stubborn components without causing further damage.

- Frequent Bearing Failures: If you find yourself replacing bearings more often than expected, it’s time to seek expert advice. This could indicate underlying issues that need to be addressed.

In these situations, don’t hesitate to reach out to a qualified technician who specializes in trailer maintenance. Regular professional assessments can help ensure that your trailer remains safe and functional.

Tow with peace of mind, knowing that trailerwatchdog is standing guard.