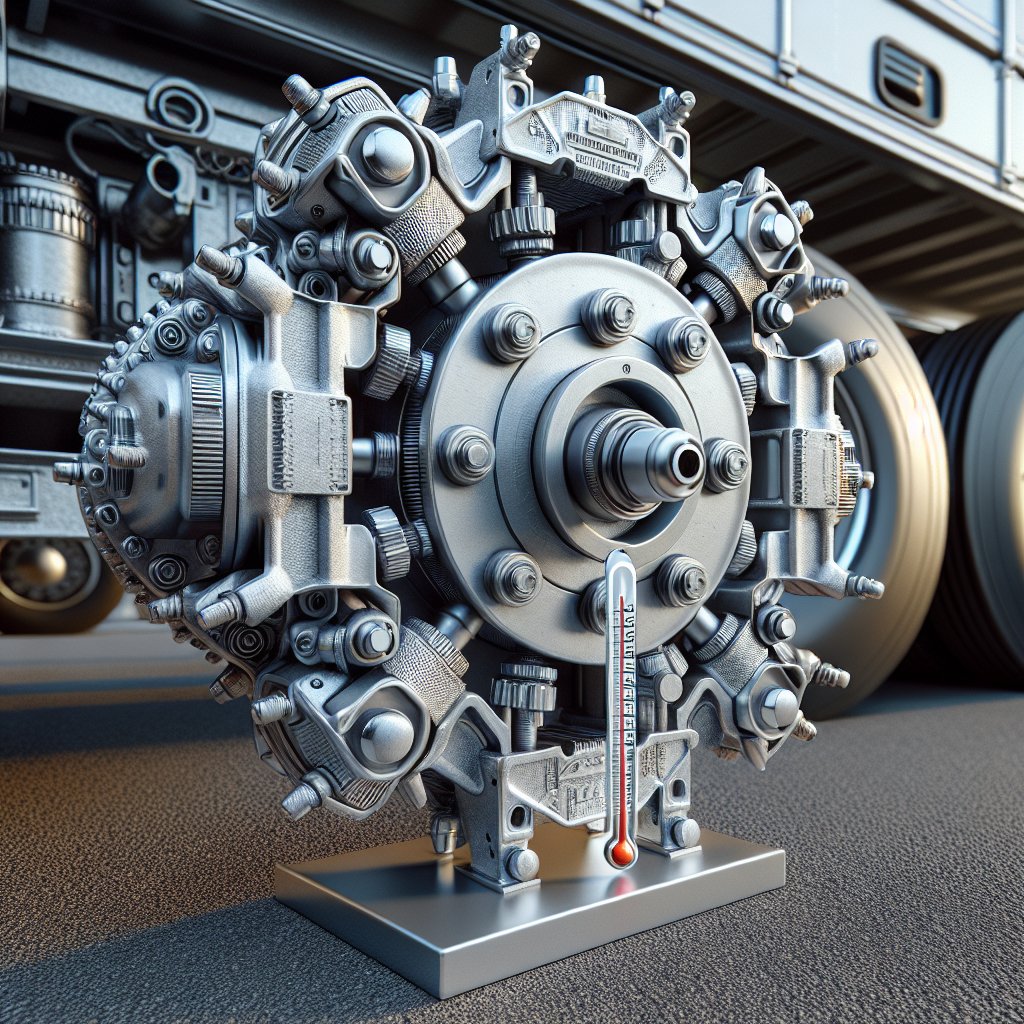

When it comes to trailer safety, understanding axle box temperature measurement is paramount. The axle box is a critical component that bears the weight of the trailer, and any significant deviation in its temperature can indicate potential failure. By monitoring this temperature, operators can effectively prevent catastrophic incidents that could arise from overheating or mechanical failure.

Effective axle box temperature measurement offers several key benefits:

- Enhanced Safety: Regular monitoring ensures that any anomalies are detected early, reducing the risk of accidents.

- Improved Trailer Performance: Keeping the temperature within optimal ranges prolongs the life of trailer components and enhances overall performance.

- Cost Savings: By preventing failures, companies can save on expensive repairs and downtime.

Integrating a reliable monitoring system is essential for any trailer operator who values safety and efficiency. With advanced technology, it’s possible to turn any trailer into a smart trailer, providing real-time data on axle box temperatures and more. Tow with peace of mind, knowing that trailerwatchdog is standing guard.

Key Techniques for Accurate Temperature Measurement

Achieving accurate axle box temperature measurement is vital for maintaining the integrity of trailer operations. Several techniques can be employed to ensure precision and reliability in temperature readings. Here are some of the key methods:

- Infrared Thermography: This non-contact method uses infrared cameras to detect temperature variations on the axle surface. It allows for quick assessments without the need for physical contact, making it ideal for monitoring multiple trailers efficiently.

- Thermocouples: These sensors are placed directly on or near the axle box to provide real-time temperature readings. They are known for their accuracy and can be integrated into existing trailer systems for continuous monitoring.

- Wireless Sensors: Emerging technologies include wireless temperature sensors that transmit data to a central monitoring system. This method enhances convenience, as it allows operators to keep track of temperature changes from a distance.

Utilizing these techniques not only enhances the reliability of temperature measurements but also facilitates proactive maintenance strategies. By implementing accurate measurement systems, operators can effectively mitigate risks associated with axle box overheating and ensure a smoother operational flow.

Choosing the Right Temperature Sensors for Trailers

Selecting the right temperature sensors for your trailer is crucial for effective axle box temperature measurement. The choice of sensor can significantly impact the accuracy and reliability of temperature readings, thus influencing operational safety and performance. Here are some key factors to consider when choosing temperature sensors:

- Type of Sensor: Different types of sensors serve various purposes. For instance, thermocouples are excellent for high-temperature environments, while infrared sensors can measure surface temperatures without contact. Evaluating the specific requirements of your trailer will help you make an informed decision.

- Temperature Range: Ensure that the sensor you choose can operate within the temperature range expected in your trailer's environment. Selecting a sensor with a broader range can provide flexibility and adaptability for various conditions.

- Response Time: The speed at which a sensor can provide a reading is vital, especially in dynamic situations. Look for sensors with fast response times to ensure timely monitoring and intervention.

- Durability and Environmental Resistance: Given the harsh conditions trailers often face, it’s essential to select sensors that are robust and resistant to environmental factors such as moisture, dust, and vibrations.

By carefully considering these factors, you can choose temperature sensors that not only meet your operational needs but also enhance the safety and longevity of your trailer.

Recognizing Signs of Overheating in Axle Boxes

Understanding and recognizing the signs of overheating in axle boxes is essential for maintaining the safety and efficiency of your trailer. Overheating can lead to catastrophic failures, resulting in costly repairs and dangerous situations on the road. Here are some key indicators to watch for:

- Excessive Heat: The most obvious sign of overheating is excessive heat emanating from the axle box. If you notice that the axle box feels significantly hotter than usual, it's a clear warning sign that something is amiss.

- Unusual Odors: An overheating axle may emit burning or acrid smells, which can signify that lubricants are breaking down or that components are beginning to overheat. Pay attention to any changes in smell during your travels.

- Increased Friction Noise: If you hear grinding or squeaking noises coming from the axle box, it may indicate that parts are overheating and failing to function smoothly. This noise often signals a need for immediate inspection.

- Visual Signs of Damage: Inspect your axle boxes regularly for any signs of discoloration, melting, or deformation. Any visual anomalies can indicate that the axle box has been subjected to excessive heat.

By being vigilant and recognizing these signs early, you can take action to prevent overheating, ensuring the safety and reliability of your trailer on the road.

Implementing a Monitoring System for Continuous Data

Implementing a monitoring system for continuous data collection is a game-changer for trailer safety and performance. Such systems are designed to provide real-time insights into critical parameters, including axle box temperature and tire conditions, helping operators maintain optimal performance and avoid potential failures.

Here are some key benefits of utilizing a continuous monitoring system:

- Real-Time Alerts: A sophisticated monitoring system can send instant alerts when it detects abnormal temperature levels or other indicators of potential failure. This allows for timely intervention, preventing catastrophic incidents before they occur.

- Data Logging: Continuous monitoring provides a wealth of data that can be logged over time. This historical data can help identify trends, assess wear and tear, and make informed maintenance decisions based on actual usage patterns.

- Enhanced Decision Making: With access to real-time data, operators can make better decisions regarding routing, maintenance schedules, and operational practices. This leads to improved overall efficiency and reduced operational costs.

- Increased Accountability: A monitoring system creates a documented trail of performance, which can enhance accountability among operators and maintenance teams. Knowing that data is being collected can encourage proactive measures to address potential issues.

By integrating a continuous monitoring system into your trailer operations, you not only safeguard your assets but also enhance the overall efficiency and longevity of your equipment.

Best Practices for Maintaining Axle Box Temperature Safety

Ensuring the safety of axle box temperature is critical for the longevity and reliability of any trailer. Adopting best practices can significantly reduce the risk of overheating and subsequent failures. Here are some essential practices to maintain optimal axle box temperature:

- Regular Inspections: Conduct routine inspections of axle components, focusing on the integrity of seals, bearings, and associated hardware. Look for signs of wear or damage that may contribute to increased friction and heat.

- Monitoring Systems: Implement a robust monitoring system that tracks axle box temperatures continuously. This allows for early detection of any anomalies, enabling timely maintenance and reducing the risk of overheating.

- Proper Lubrication: Ensure that axle boxes are adequately lubricated according to manufacturer specifications. Proper lubrication minimizes friction and heat generation, significantly lowering the risk of temperature spikes.

- Load Management: Pay close attention to the load limits of your trailer. Overloading can lead to excessive heat in the axle boxes. Adhering to recommended weight limits helps maintain safe operational temperatures.

- Environmental Considerations: Be mindful of operating conditions. Extreme temperatures, steep inclines, and prolonged stop-and-go traffic can affect axle temperatures. Adjust your driving practices accordingly to mitigate these effects.

By following these best practices, you can enhance the safety and performance of your trailer. Remember, it's crucial to tow with peace of mind, knowing that trailerwatchdog is standing guard.