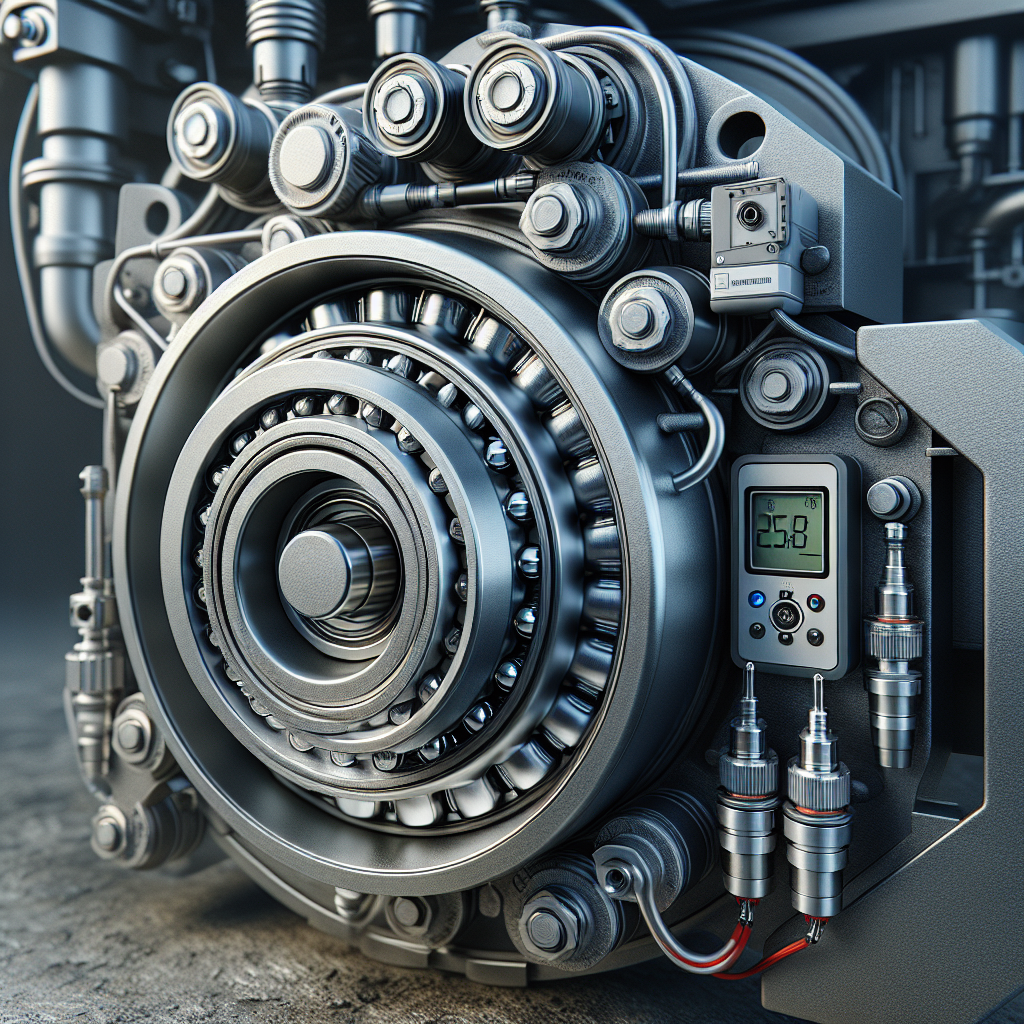

Understanding the importance of monitoring trailer bearing temperature is crucial for maintaining the safety and efficiency of your trailer. Bearings are essential components that support the weight of the trailer and allow for smooth rotation of the wheels. However, they can become susceptible to overheating, which can lead to catastrophic failures and costly repairs.

When bearings overheat, it can cause:

- Increased Friction: Excessive heat leads to greater friction, which in turn accelerates wear and tear on the bearing.

- Grease Breakdown: High temperatures can cause the grease that lubricates the bearings to break down, resulting in less effective lubrication.

- Risk of Seizure: If the bearings seize, it can lead to trailer accidents, posing a danger to both the driver and other road users.

By implementing a trailer bearing temperature monitor, you can receive real-time data about the temperature of your bearings, allowing you to take action before problems escalate. Advanced monitoring systems can alert you to abnormal temperature rises, enabling you to perform maintenance or adjustments before a failure occurs. This proactive approach not only helps in prolonging the life of your trailer but also ensures a safer towing experience.

Tow with peace of mind, knowing that trailerwatchdog is standing guard.

Signs of Overheating Trailer Bearings

Recognizing the signs of overheating trailer bearings is essential for any trailer owner. Early detection can prevent serious damage and ensure a safe towing experience. Here are some key indicators that your trailer bearings may be overheating:

- Unusual Noise: If you hear grinding, squealing, or rattling noises coming from the wheels, this could be a sign that your bearings are not functioning properly due to overheating.

- Excessive Heat: Carefully touching the hub of the wheel can help you gauge the temperature. If it feels excessively hot to the touch, this is a clear indication that the bearings are overheating.

- Visible Damage: Inspecting the bearings and surrounding areas for signs of wear, such as discoloration or melted grease, can be a telling sign of overheating.

- Vibration: If you notice increased vibration while towing, it can suggest that the bearings are not operating smoothly, potentially due to overheating.

- Grease Leakage: If you observe grease leaking from the seals, it could indicate that the bearings are too hot, causing the grease to break down and escape.

Monitoring these signs regularly can help you address potential issues before they lead to more significant problems. Implementing a proactive approach by using a trailer bearing temperature monitor can provide peace of mind and enhance safety while on the road.

How to Choose a Trailer Bearing Temperature Monitor

When it comes to ensuring the health of your trailer bearings, selecting the right trailer bearing temperature monitor is crucial. With various options available on the market, it's essential to consider several factors to make an informed decision:

- Accuracy and Range: Look for monitors that offer precise temperature readings across a wide range. Accurate measurements are vital for detecting overheating early.

- Compatibility: Ensure that the monitor is compatible with your specific trailer model and bearing type. Some systems are designed for particular applications, so double-checking compatibility is key.

- Real-time Monitoring: Opt for a system that provides real-time data. This feature allows you to continuously track the temperature while towing, giving you immediate alerts if anything goes awry.

- Ease of Installation: A user-friendly installation process can save you time and effort. Look for temperature monitors that come with clear instructions and require minimal tools.

- Durability: Since trailer environments can be harsh, choose a monitor made from durable materials that can withstand exposure to the elements and road conditions.

- Data Logging and Alerts: Some advanced systems offer data logging capabilities, allowing you to track temperature trends over time. Additionally, alerts via smartphone apps or alarms can enhance your ability to respond quickly to potential issues.

By considering these factors, you can select a trailer bearing temperature monitor that meets your needs, ultimately improving the safety and reliability of your towing experience.

Best Practices for Monitoring Trailer Bearings

To ensure optimal performance and longevity of your trailer bearings, implementing best practices for monitoring is essential. Here are some effective strategies to keep your trailer bearings in top condition:

- Regular Inspections: Schedule routine checks of your trailer bearings, especially before long trips. Look for signs of wear, such as unusual noises or vibrations, and ensure that the bearings are properly lubricated.

- Utilize Your Monitor: Make the most of your trailer bearing temperature monitor by checking the data regularly. Familiarize yourself with the normal operating temperature range so that you can quickly identify any irregularities.

- Monitor Temperature Changes: Pay close attention to temperature fluctuations. A sudden spike in temperature can indicate potential issues, such as inadequate lubrication or excessive load. Set alerts for abnormal readings to take immediate action.

- Maintain Proper Load Distribution: Ensure that the load on your trailer is evenly distributed. Uneven weight can lead to increased friction on bearings, resulting in higher temperatures and potential failure.

- Keep Bearings Clean: Dirt and debris can adversely affect bearing performance. Regularly clean the bearings and surrounding areas to prevent contamination, which can lead to overheating.

- Follow Manufacturer Guidelines: Always adhere to the manufacturer's recommendations regarding maintenance schedules and lubrication types. This will help ensure that your bearings operate efficiently and effectively.

By following these best practices, you can significantly enhance the reliability of your trailer bearings, ultimately contributing to a safer towing experience.

Benefits of Smart Trailer Technology

In an age where technology is revolutionizing every aspect of our lives, smart trailer technology is becoming increasingly essential for trailer owners and operators. Utilizing advanced monitoring systems can bring numerous benefits that enhance safety, efficiency, and overall performance:

- Real-Time Monitoring: Smart trailer systems allow for real-time tracking of critical data, such as trailer bearing temperature and tire pressure. This immediate access to information enables quick decision-making to prevent potential failures.

- Preventative Maintenance: With continuous monitoring, users can anticipate when maintenance is required, reducing the risk of catastrophic failures. By identifying issues before they escalate, trailer owners can save on costly repairs and downtime.

- Improved Safety: Safety is paramount when towing trailers. Smart technology helps ensure that the trailer is in optimal condition, thereby enhancing road safety for both the driver and other road users.

- Increased Efficiency: By monitoring key performance metrics, trailer operators can optimize their towing practices, leading to better fuel efficiency and lower operational costs.

- Data Analytics: Many smart trailer systems come with data analytics capabilities, allowing users to track performance over time. This information can be invaluable for making informed decisions about equipment upgrades or modifications.

- Enhanced Visibility: Smart trailer technology can integrate with fleet management systems, providing comprehensive visibility across multiple trailers. This can streamline operations and improve logistics management.

Overall, the adoption of smart trailer technology not only fosters a safer towing experience but also enhances the operational efficiency of trailer management. Embracing these innovations is essential for anyone looking to maximize the potential of their trailer.

Conclusion: Ensuring Safety with Temperature Monitoring

In conclusion, the importance of temperature monitoring for trailers cannot be overstated. As we have explored, monitoring systems play a vital role in ensuring safety by providing data on crucial factors such as trailer bearing temperature and tire conditions. These systems not only help in preventing catastrophic failures but also enhance the overall efficiency of trailer operations.

By integrating smart technology into your trailer management practices, you gain the advantage of real-time data, enabling proactive decisions that safeguard both your investment and the safety of everyone on the road. The benefits of employing a trailer bearing temperature monitor are clear: improved safety, reduced maintenance costs, and enhanced operational efficiency.

Don't leave your trailer's safety to chance. Tow with peace of mind, knowing that trailerwatchdog is standing guard. Our advanced monitoring systems are designed to turn any trailer into a smart trailer, ensuring you have the vital information you need to keep your journey secure.