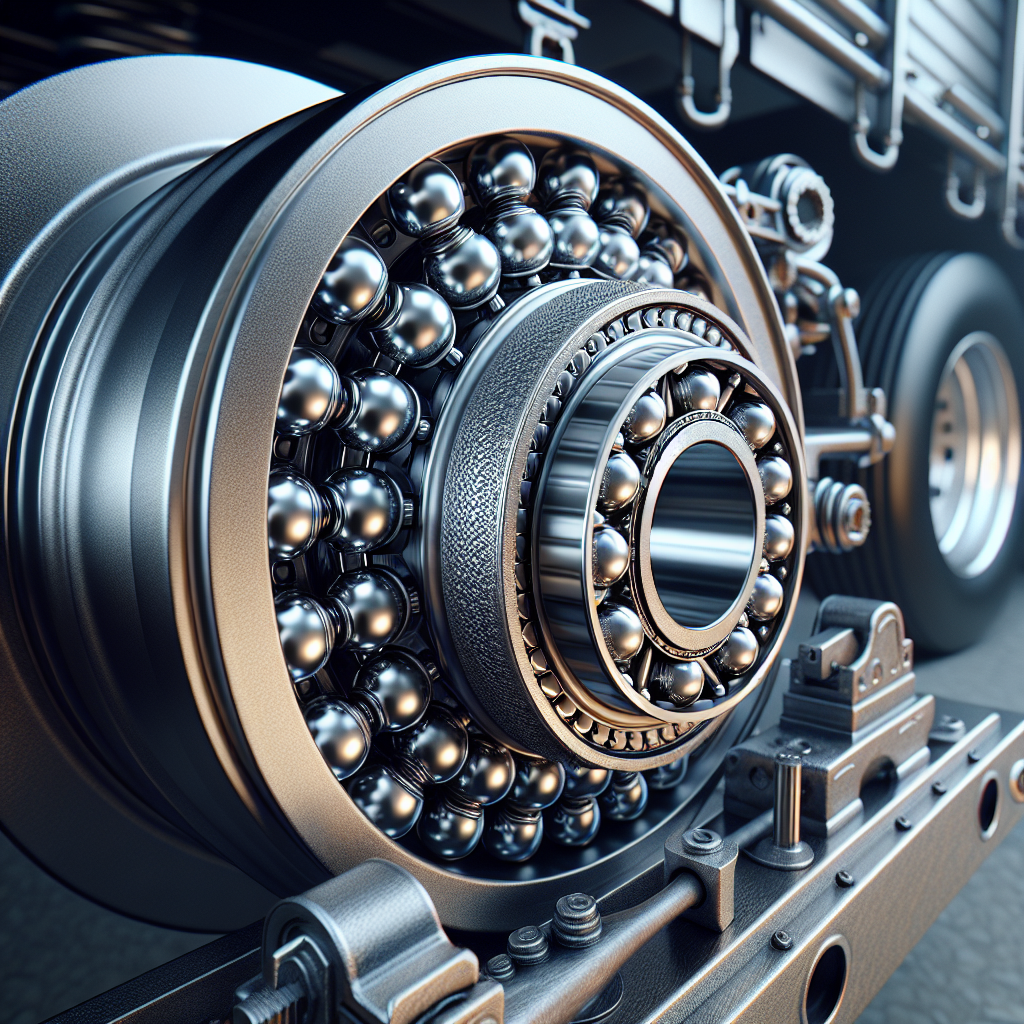

Trailer wheel bearings play a crucial role in the overall functionality and safety of your trailer. They are designed to support the weight of the trailer while allowing the wheels to rotate freely. Understanding how these components work can help you identify potential trailer wheel bearing failure symptoms before they escalate into serious issues.

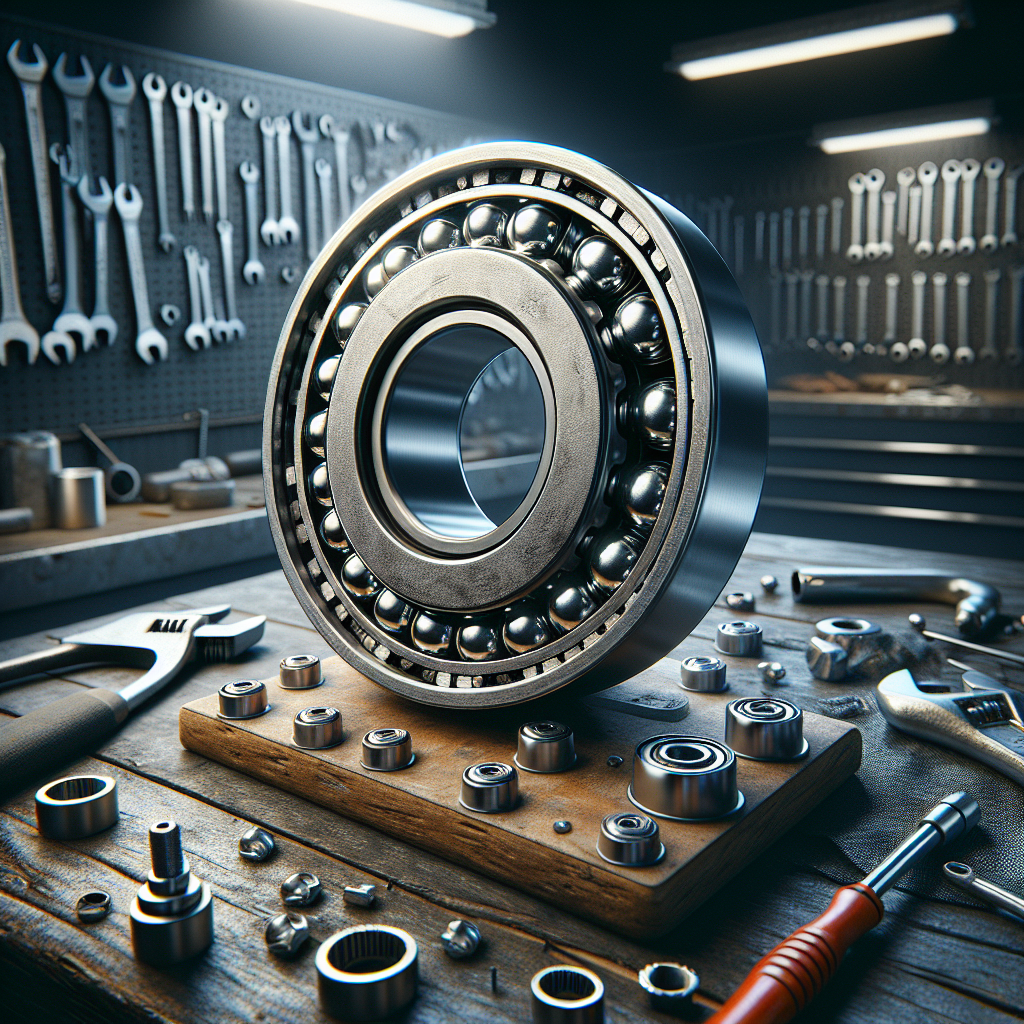

At the core, trailer wheel bearings consist of a set of metal balls or rollers that are housed in a circular race. This design minimizes friction and distributes the load evenly, which is essential for smooth operation. Here are some key functions of trailer wheel bearings:

- Load Distribution: They support the weight of the trailer and evenly distribute the load across the wheel.

- Smooth Rotation: The design allows for minimal friction, enabling the wheels to rotate freely.

- Heat Dissipation: By reducing friction, bearings help dissipate heat, preventing overheating that can lead to failure.

- Alignment Maintenance: They ensure that the wheels remain aligned, which is essential for safe towing and tire longevity.

Neglecting the maintenance of your trailer wheel bearings can lead to catastrophic failures, resulting in costly repairs and safety hazards. It's essential to regularly inspect and monitor their condition. Tow with peace of mind, knowing that trailerwatchdog is standing guard.

Common Symptoms of Wheel Bearing Failure

Recognizing the common symptoms of wheel bearing failure is vital for maintaining the safety and efficiency of your trailer. Prompt identification of these symptoms can prevent further damage and ensure safer towing experiences. Here are some key indicators to watch for:

- Unusual Noises: A grinding, humming, or growling noise from the wheel area is often the first sign of bearing wear. This sound can become more pronounced during turns or at higher speeds.

- Vibration: Excessive vibration felt through the trailer can indicate that the bearings are failing. This vibration may worsen as you increase speed.

- Play in the Wheel: If you notice any play or looseness when rocking the wheel back and forth, it could be a sign that the bearings are worn out or damaged.

- Heat Generation: Overheating of the wheel hub can be a direct result of failing bearings. If you touch the hub and it feels excessively hot, it's a crucial warning sign.

- Uneven Tire Wear: If your tires are wearing unevenly, it may indicate that the wheel bearings are not functioning correctly, leading to misalignment.

Being proactive in monitoring these symptoms can save you from more severe issues down the line. Regular maintenance and inspection of your trailer's wheel bearings are essential for safe operation.

How to Diagnose Wheel Bearing Issues

Diagnosing wheel bearing issues is crucial for ensuring the safety and reliability of your trailer. Here’s a structured approach to help you identify potential problems:

- Visual Inspection: Start with a thorough visual inspection of your wheels and bearings. Look for signs of wear, corrosion, or physical damage. Check for any grease leaks or dirt accumulation around the hub.

- Noise Assessment: Drive your trailer at various speeds and listen closely for any unusual noises. If you hear grinding, humming, or any irregular sounds originating from the wheel area, it may indicate a bearing problem.

- Check for Play: With the trailer securely lifted, grab the wheel at the top and bottom and shake it gently. If you detect any movement or play, this could signal that the bearings are worn out.

- Temperature Test: After driving, carefully touch the wheel hub to check its temperature. If the hub is significantly hotter than the others, it could mean that the bearings are failing.

- Wheel Alignment: Inspect the alignment of the wheels. If they appear to be misaligned or the trailer pulls to one side, it may be due to bad wheel bearings.

By following these diagnostic steps, you can effectively identify wheel bearing issues before they escalate into more serious problems. Regular checks and early detection will keep your trailer safe on the road.

Preventive Measures for Avoiding Failure

Implementing preventive measures is essential for avoiding wheel bearing failure and ensuring the longevity of your trailer. Here are several key strategies to consider:

- Regular Maintenance: Schedule routine maintenance checks for your trailer. This includes inspecting the wheel bearings, ensuring they are properly lubricated, and replacing grease as needed to avoid contamination.

- Quality Components: Invest in high-quality bearings and components. Using reputable brands can significantly reduce the risk of premature failure.

- Monitor Load Capacity: Adhere to the manufacturer’s recommended load limits. Overloading can put excessive stress on the bearings, leading to overheating and failure.

- Check Alignment: Regularly verify that your trailer wheels are properly aligned. Misalignment can cause uneven wear on the bearings and increase the likelihood of failure.

- Environmental Protection: Protect your trailer from harsh environmental conditions. Use covers or store the trailer in a sheltered area to prevent dirt, moisture, and debris from affecting the wheel bearings.

By taking these preventive measures, you can significantly reduce the risk of wheel bearing failure and extend the life of your trailer. Consistent upkeep and attention to detail are key to maintaining optimal trailer performance.

When to Replace Trailer Wheel Bearings

Knowing when to replace your trailer wheel bearings is crucial for maintaining the safety and functionality of your trailer. Here are some signs that indicate it may be time for a replacement:

- Excessive Noise: If you hear grinding, squeaking, or rumbling noises coming from the wheel area, it may indicate that the bearings are worn out and need replacement.

- Heat Generation: Overheating is a significant warning sign. If the wheel hub feels excessively hot to the touch after a short drive, this could signal that the bearings are failing.

- Play or Movement: Check for any play in the wheel. If you can wiggle the wheel while it’s off the ground, this indicates that the bearings may be excessively worn and require replacing.

- Visible Damage: During inspections, look for any signs of damage or wear on the bearings themselves. Pitting, rust, or discoloration are clear indicators that it's time for a replacement.

- Unusual Tire Wear: If you notice that your trailer tires are wearing unevenly, this could be a sign of failing bearings affecting wheel alignment.

Replacing trailer wheel bearings promptly can prevent further damage and ensure safe towing. Regular inspections and awareness of these signs can save you from catastrophic failure and costly repairs in the long run.

Importance of Regular Trailer Maintenance

Regular trailer maintenance is essential for ensuring the longevity and safety of your trailer. Just like any other vehicle, trailers require routine checks and servicing to function optimally and prevent potential issues.

Here are some key reasons why regular maintenance should be a priority:

- Safety: A well-maintained trailer reduces the risk of accidents caused by mechanical failures. Regular inspections can identify potential issues, such as worn tires or faulty brakes, before they lead to significant problems.

- Cost-Effectiveness: Investing time and resources in regular maintenance can save you money in the long run. Addressing minor issues early can prevent them from developing into major repairs that are much more costly.

- Improved Performance: Regularly checking and servicing components like bearings, brakes, and tires ensures that your trailer operates at peak performance. This not only enhances your towing experience but also increases fuel efficiency.

- Increased Resale Value: A well-maintained trailer retains its value over time. Keeping documentation of regular maintenance can be a selling point if you decide to sell your trailer in the future.

To ensure your trailer remains in top condition, consider implementing a routine maintenance schedule and utilizing monitoring systems like TrailerWatchdog. With its advanced technology, you can monitor axle temperature and tire data, helping to prevent catastrophic failures and keeping your trailer safe on the road. Tow with peace of mind, knowing that TrailerWatchdog is standing guard.