Trailer wheel bearings play a critical role in ensuring the smooth operation of your trailer. They are designed to support the weight of the trailer while allowing the wheels to rotate freely, reducing friction and wear over time. Understanding how these components function is essential for any trailer owner looking to enhance safety and performance.

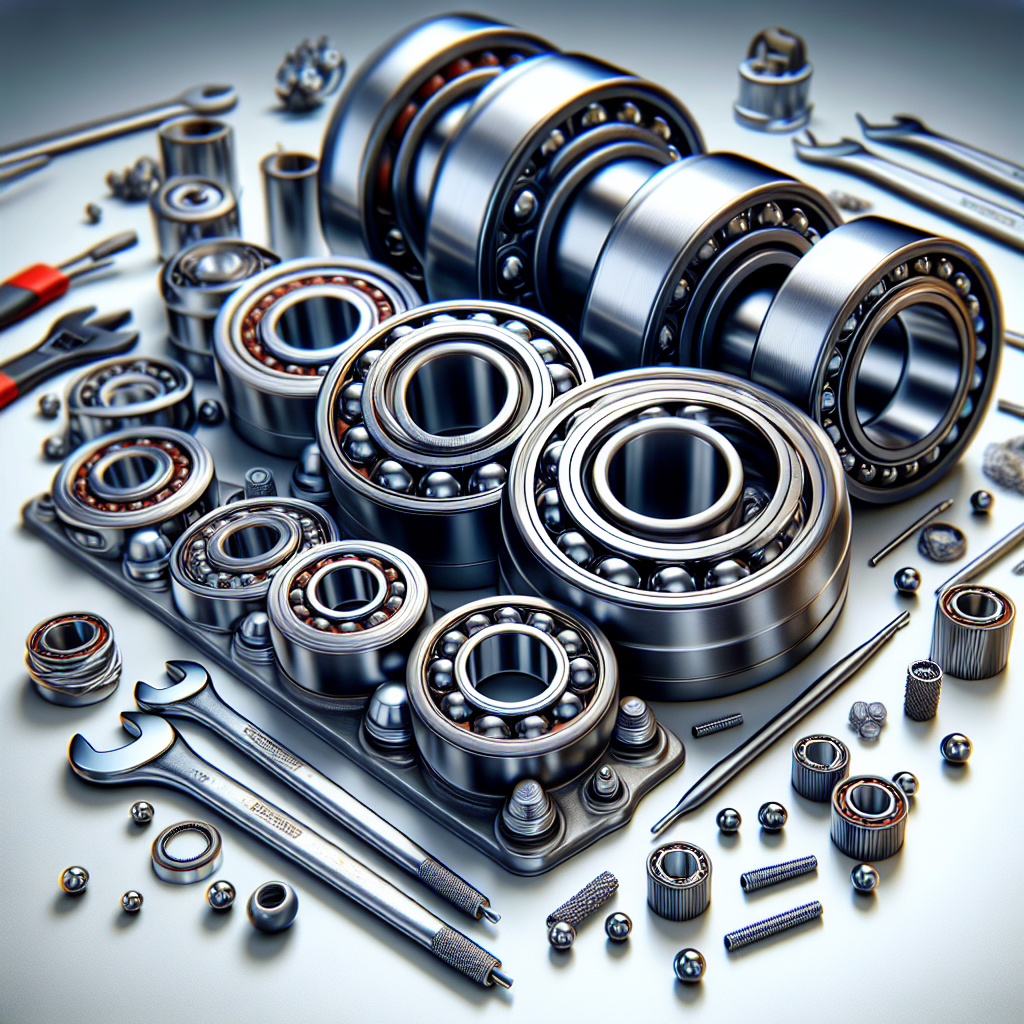

Wheel bearings consist of several parts, including the inner and outer races, rollers or balls, and a seal. These components work together to maintain the alignment of the wheel and provide a stable connection to the axle. When properly maintained, trailer wheel bearings can significantly improve the lifespan of your trailer by minimizing energy loss and preventing overheating.

However, neglecting wheel bearing maintenance can lead to catastrophic failures. Signs of wear may include:

- Unusual noises while towing, such as grinding or humming

- Excessive play in the wheel

- Visible grease leakage

- Overheating of the wheel hub

Regular inspection and timely replacement of worn bearings are crucial for maintaining optimal performance. By integrating a trailer monitoring system, you can keep tabs on the condition of your wheel bearings, enhancing safety and reliability on the road.

Tow with peace of mind, knowing that trailerwatchdog is standing guard.

Signs of Wheel Bearing Movement Issues

Detecting issues with trailer wheel bearings early can save you from potential accidents and costly repairs. Being aware of the signs of wheel bearing movement issues is essential for any trailer owner. Here are some key indicators that may suggest your wheel bearings are experiencing problems:

- Unusual Noises: One of the most common signs is hearing a grinding, rumbling, or humming sound from the wheel area. This noise often indicates that the bearings are worn out or damaged.

- Excessive Wheel Play: If you notice excessive movement in the wheel when you try to shake it side to side, it might be a sign that the wheel bearings are no longer holding the wheel snugly.

- Heat Generation: If the hub feels excessively hot to the touch after a short drive, it could indicate that the bearings are failing and creating friction.

- Grease Leakage: Visible grease around the wheel hub or on your tire can indicate that the seals have failed, allowing lubricant to escape and exposing the bearings to contaminants.

- Vibration: A pronounced vibration felt throughout the trailer while driving can also signal that the bearings are not functioning correctly, which may lead to further damage if not addressed.

By keeping an eye on these warning signs, you can take proactive steps to maintain your trailer’s wheel bearings and ensure a safer towing experience.

Impact of Poor Wheel Bearing Maintenance

Neglecting proper maintenance of trailer wheel bearings can lead to a cascade of issues that not only compromise the integrity of your trailer but also pose safety risks on the road. Understanding the impact of poor wheel bearing maintenance is crucial for any trailer operator. Here are some consequences of inadequate care:

- Increased Wear and Tear: Failing to regularly inspect and lubricate wheel bearings can accelerate wear, leading to premature failure. This not only increases repair costs but also disrupts your towing schedule.

- Overheating: Insufficient lubrication causes bearings to generate excessive heat. This overheating can lead to a breakdown of bearing materials, resulting in catastrophic failure while on the road.

- Reduced Traction and Control: Worn or damaged bearings can affect the alignment of your trailer wheels. This misalignment can lead to poor handling, making it difficult to control your trailer and increasing the risk of accidents.

- Brake System Complications: Poorly maintained wheel bearings can also affect the trailer’s braking system. Increased friction can lead to longer stopping distances, creating potential hazards during emergency situations.

- Higher Replacement Costs: Ultimately, neglecting wheel bearing maintenance can result in needing to replace not just the bearings, but also other related components, leading to higher repair bills.

Regular maintenance and monitoring of your trailer’s wheel bearings are essential for ensuring safety and longevity. Taking the time to care for these components can prevent more serious issues down the line.

Best Practices for Trailer Wheel Bearing Care

Maintaining your trailer wheel bearings is essential for ensuring safe and efficient towing. By following established best practices, you can significantly enhance the lifespan of your trailer. Here are some key practices to consider:

- Regular Inspections: Conduct routine visual inspections of your wheel bearings. Look for signs of wear, such as discoloration, pitting, or unusual sounds during operation. Addressing these issues early can prevent bigger problems.

- Proper Lubrication: Ensure that wheel bearings are adequately lubricated with suitable grease. Over time, grease can break down, so it’s important to repack bearings as per the manufacturer’s recommendations to maintain optimal performance.

- Temperature Monitoring: Implement a smart monitoring system to keep an eye on axle temperatures. Consistently high temperatures can indicate potential bearing failure and can help you take preventive measures before a catastrophic event occurs.

- Correct Installation: When replacing or installing new bearings, ensure they are fitted correctly. Improper installation can lead to misalignment and excessive wear, which can compromise trailer safety.

- Seasonal Maintenance: Adapt your maintenance routine to seasonal changes. For example, if you frequently tow in extreme heat or cold, consider more frequent inspections to ensure your bearings remain in optimal condition.

By adopting these best practices, you can enhance the reliability of your trailer and promote safe towing. Investing time and effort into wheel bearing care pays off in the long run, keeping you and your cargo secure on the road.

How Trailer Monitoring Systems Enhance Safety

In today's fast-paced world, ensuring the safety of your trailer while on the road is more crucial than ever. Trailer monitoring systems serve as a vital tool for enhancing safety and preventing potential failures that could lead to catastrophic incidents. Here’s how these systems contribute to safer towing experiences:

- Real-Time Data Monitoring: Modern trailer monitoring systems provide real-time data on various parameters, including axle temperature and tire pressure. This immediate feedback allows trailer owners to identify issues before they escalate, ensuring timely interventions.

- Predictive Maintenance: By analyzing historical data, these systems can predict when maintenance is required. This proactive approach helps in planning maintenance activities, thus avoiding unexpected breakdowns and costly repairs.

- Alerts and Notifications: Users receive alerts for abnormal conditions, such as overheating or low tire pressure. These notifications can be sent directly to smartphones or other devices, enabling quick responses to mitigate risks.

- Improved Load Monitoring: Effective monitoring systems can also track load distribution and weight, ensuring that the trailer is not overloaded. Proper load management enhances the trailer's handling and braking capabilities, contributing to overall safety.

- Enhanced Driver Awareness: With integrated monitoring systems, drivers are more aware of their trailer’s condition. This heightened awareness can lead to safer driving behaviors and better decision-making on the road.

Integrating a trailer monitoring system not only improves the safety of your trailer but also gives you peace of mind while towing. As technology continues to evolve, these systems play an indispensable role in ensuring the longevity and reliability of trailers.

Conclusion on Maintaining Trailer Wheel Bearings

Maintaining your trailer's wheel bearings is essential for ensuring optimal performance and safety during your travels. As we've explored, the movement of trailer wheel bearings can significantly impact the overall functionality of your trailer, making regular inspection and maintenance critical. Neglecting this aspect can lead to wear and tear, which could ultimately result in serious breakdowns or accidents.

To effectively maintain your trailer wheel bearings, consider the following best practices:

- Regular Inspections: Conduct frequent inspections of wheel bearings to check for signs of wear, such as unusual noises or overheating.

- Proper Lubrication: Ensure that wheel bearings are adequately lubricated to reduce friction and wear. Use the appropriate type of grease recommended for your trailer.

- Replace Worn Components: If you notice any damage or excessive wear, replace the bearings promptly to avoid further issues.

- Utilize Monitoring Technology: Integrating a trailer monitoring system can provide real-time data and alerts related to wheel bearing conditions, enhancing both safety and maintenance efforts.

By adhering to these maintenance practices, you can significantly extend the life of your trailer and ensure safer travels. Tow with peace of mind, knowing that trailerwatchdog is standing guard.