Trailer bearings are essential components that play a vital role in the smooth operation of any trailer. They are designed to reduce friction between the trailer's axle and wheel hub, allowing for easy rotation of the wheels. Understanding the importance of trailer bearings is crucial for both safety and efficiency on the road.

Why are trailer bearings important? Here are a few key reasons:

- Safety: Worn or damaged bearings can lead to wheel lock-up or complete failure, posing a serious risk on the road.

- Performance: Properly functioning bearings ensure that your trailer wheels turn smoothly, improving fuel efficiency during towing.

- Longevity: Regular maintenance of trailer bearings can extend the lifespan of both the bearings and the trailer itself, saving you money in the long run.

It is essential to choose the right type and size of bearings suitable for your specific trailer model. This will not only enhance performance but also provide peace of mind while you tow. When considering what trailer bearings do I need, consult with a professional or refer to your trailer's specifications.

Tow with peace of mind, knowing that trailerwatchdog is standing guard.

Types of Trailer Bearings Available on the Market

When it comes to selecting the right trailer bearings, it's essential to understand the various types available on the market. Each type serves a specific purpose and is designed to meet different operational needs. Here are the most common types of trailer bearings:

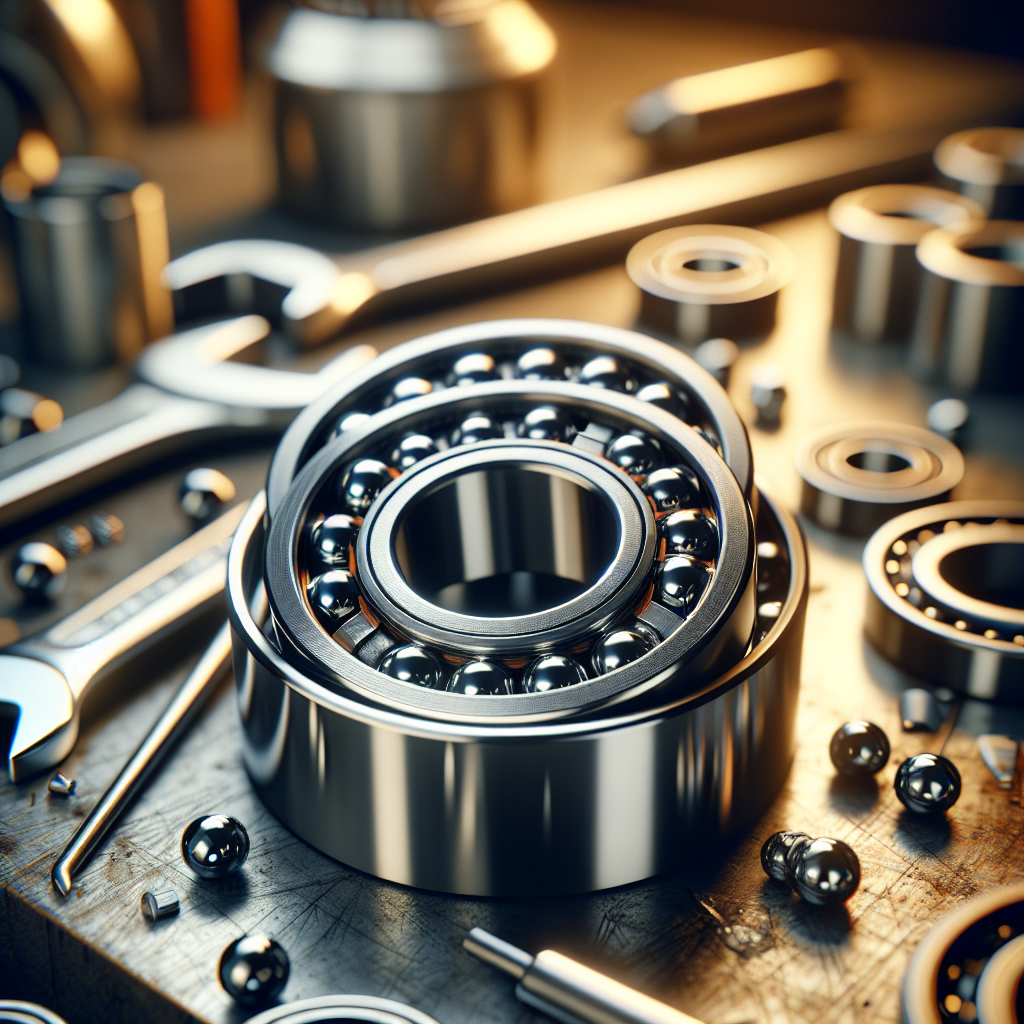

- Ball Bearings: These are the most common type of trailer bearings, consisting of small spherical balls that allow for smooth rotation. They are ideal for lightweight trailers and are easy to install and maintain.

- Roller Bearings: Roller bearings use cylindrical rollers instead of balls. They can handle heavy loads more efficiently and are commonly found in larger trailers. Their design minimizes friction and increases load capacity.

- Needle Bearings: A variant of roller bearings, needle bearings use long, thin rollers (needles) that provide a larger contact surface area. They are excellent for high-load applications and can be found in heavy-duty trailers.

- Self-Aligning Bearings: These bearings are designed to accommodate misalignment between the axle and wheel hub. They are particularly useful for trailers that may experience uneven wear and tear.

- Sealed Bearings: Sealed bearings come pre-lubricated and are enclosed in a protective casing. This design prevents the ingress of dirt and moisture, making them low-maintenance and ideal for trailers used in harsh conditions.

Choosing the right type of bearing is crucial for the overall performance and safety of your trailer. Ensure that you assess your trailer's requirements and match them with the appropriate bearing type for optimal results.

How to Identify the Correct Size for Your Trailer

Identifying the correct size for your trailer bearings is vital for ensuring a safe and efficient towing experience. Using the wrong size can lead to premature wear, overheating, and even catastrophic failure. Here are some steps to help you determine the right size for your trailer:

- Check the Existing Bearings: If you’re replacing old bearings, start by removing the hub and inspecting the existing bearings. Look for any part numbers or markings that indicate the size.

- Measure the Inner and Outer Diameters: Use a caliper or a micrometer to measure the inner diameter (ID) and outer diameter (OD) of the bearings. These measurements are crucial for finding the correct replacement.

- Determine the Width: Measure the width of the bearing. This is often overlooked but is important for proper fit within the axle and hub.

- Consult Manufacturer Specifications: Refer to your trailer's owner manual or the manufacturer’s website for specific information on bearing sizes. This can save you time and ensure compatibility.

- Consider Load Ratings: Ensure that the bearing size you choose can handle the weight of your trailer. Each bearing has a load rating that indicates its capacity to carry weight safely.

By following these steps, you can confidently select the correct bearing size, ensuring your trailer operates smoothly and safely on the road.

Factors Influencing the Selection of Trailer Bearings

Selecting the right trailer bearings is not just about size; several critical factors can influence your decision. Understanding these aspects can help you make an informed choice that enhances the performance and longevity of your trailer. Here are the key factors to consider:

- Load Capacity: The weight your trailer carries directly impacts the type of bearings you need. Bearings are rated for load capacity, so ensure that the selected bearings can handle the maximum weight of your trailer and its cargo.

- Speed Rating: If you plan to tow your trailer at high speeds, it's essential to choose bearings designed for such conditions. High-speed bearings can reduce friction and heat buildup, enhancing performance.

- Environmental Conditions: Consider the conditions in which you will be using your trailer. If you frequently travel in wet or corrosive environments, opt for bearings that provide better sealing against water and contaminants.

- Material Composition: Bearings are made from various materials, including steel, ceramic, and plastic. Each material offers different benefits, such as weight reduction or increased durability. Choose based on your specific needs and usage.

- Maintenance Requirements: Some bearings require regular maintenance, while others are designed for minimal upkeep. If you prefer a low-maintenance solution, consider sealed bearings that don’t need frequent lubrication.

Taking these factors into account will help you choose the right trailer bearings, leading to improved safety, efficiency, and performance on the road.

Maintenance Tips for Trailer Bearings Longevity

Proper maintenance of trailer bearings is crucial for ensuring their longevity and optimal performance. Neglecting this aspect can lead to premature wear, costly repairs, or even catastrophic failure. Here are some effective maintenance tips to keep your trailer bearings in top shape:

- Regular Inspection: Schedule routine inspections to check for signs of wear, damage, or overheating. Look for any rust, discoloration, or unusual noises during towing, which may indicate bearing issues.

- Greasing: Ensure that your bearings are adequately lubricated. Depending on the type of bearings you have, they may require periodic greasing. Use the appropriate lubricant and follow the manufacturer's recommendations for frequency and quantity.

- Seal Integrity: Check the seals of your bearings regularly. Damaged or worn seals can allow dirt and moisture to enter, compromising the lubrication and leading to faster wear. Replace seals if they show any signs of deterioration.

- Temperature Monitoring: Consider installing a temperature monitoring system for your trailer bearings. Elevated temperatures can indicate potential problems. Installing a system like TrailerWatchdog can help you monitor axle temperature and prevent catastrophic failures.

- Proper Loading: Avoid overloading your trailer, as excessive weight can put undue strain on the bearings, causing them to wear out more quickly. Always adhere to the load capacity specifications of your trailer.

By following these maintenance tips, you can significantly extend the life of your trailer bearings, ensuring safe and reliable towing for years to come.

Common Problems and Solutions for Trailer Bearings

Understanding common problems associated with trailer bearings can help you address issues before they escalate into serious failures. Here are some typical problems you might encounter along with effective solutions:

- Overheating: One of the most frequent issues is overheating, which can be caused by improper lubrication, excessive load, or misalignment. Solution: Regularly check and maintain proper lubrication levels, and ensure that your trailer is not overloaded. Consider investing in a monitoring system to keep track of axle temperatures.

- Excessive Wear: Bearings that show signs of excessive wear may result from poor maintenance or low-quality components. Solution: Conduct routine inspections and replace any worn bearings promptly. Opt for high-quality bearings to ensure better durability.

- Noise: Unusual sounds while towing often indicate a problem with the bearings. Grinding or squeaking noises can suggest that the bearings are damaged or that the lubrication has run dry. Solution: Immediately inspect the bearings and lubricate or replace them as necessary.

- Grease Leaks: Grease leaking from the bearing seals is a sign that the seals may be damaged or that there is an over-greasing issue. Solution: Check the seals for wear and replace them if they are compromised. Make sure to follow the manufacturer’s specifications for greasing.

- Corrosion: Exposure to moisture can lead to rust and corrosion on the bearings, which compromises their integrity. Solution: Store your trailer in a dry place and use corrosion-resistant bearings to minimize this risk.

By being proactive and addressing these common problems, you can help ensure the reliability and safety of your trailer. Tow with peace of mind, knowing that trailerwatchdog is standing guard.