In the world of trailer safety, trailer temperature mapping plays a pivotal role in ensuring the efficiency and longevity of your equipment. This process involves the systematic collection and analysis of temperature data from various components of a trailer, particularly the axles and tires. Understanding these temperature patterns can be crucial in preventing potential failures that may lead to costly damages or hazardous situations.

The significance of temperature mapping lies in its ability to:

- Identify Overheating Issues: Continuous monitoring can quickly reveal if any component is running hotter than normal, indicating that immediate action is required.

- Enhance Performance: By understanding temperature fluctuations, operators can make informed decisions about maintenance and repairs, ensuring that trailers operate at peak performance.

- Prevent Catastrophic Failures: By catching potential failures early, companies can avoid catastrophic incidents, such as tire blowouts or axle failures, which could jeopardize safety and incur significant costs.

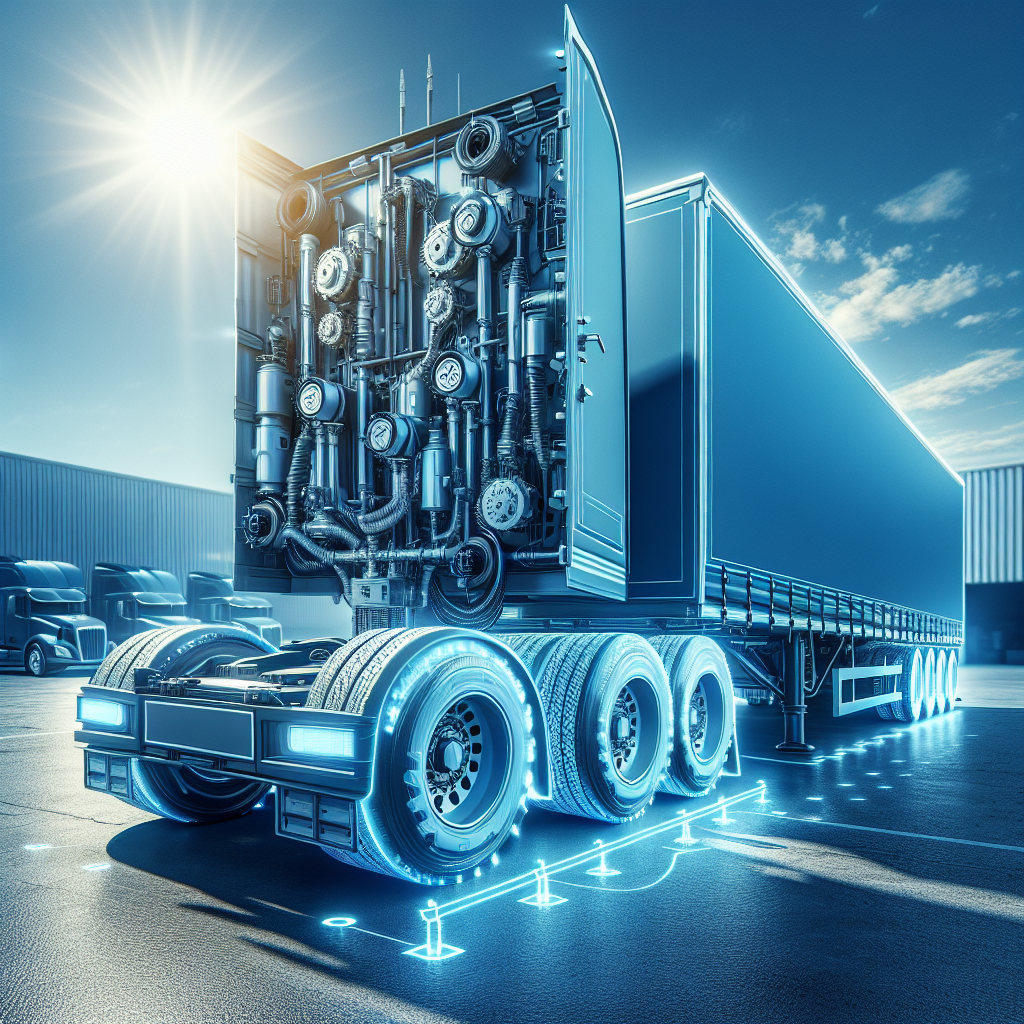

With the advent of smart trailers, the integration of trailer temperature mapping systems has become more accessible than ever. This technology not only provides real-time data but can also be integrated into broader fleet management systems to enhance overall operational efficiency.

Tow with peace of mind, knowing that trailerwatchdog is standing guard.

How Temperature Affects Trailer Performance and Safety

Temperature plays a crucial role in the overall performance and safety of trailers. Understanding how varying temperature levels affect different components can significantly enhance the longevity of your equipment and ensure safe transportation.

Firstly, let’s consider the impact of temperature on tire performance. Tires are designed to operate within specific temperature ranges. As temperatures rise, the rubber can become softer, leading to increased wear and the potential for blowouts. Conversely, cold temperatures can cause the rubber to harden, reducing traction and making tires more susceptible to damage. Regular monitoring of tire temperatures can help in maintaining optimal performance and preventing unexpected failures.

Next, the axle temperature is equally important. Excessive heat in the axle can indicate insufficient lubrication or mechanical issues, which can lead to axle failure. This not only impacts the trailer's performance but also poses a significant safety risk to the vehicle and its cargo. Maintaining a consistent temperature in the axle can help ensure smoother operation and extend the lifespan of the trailer.

Moreover, temperature fluctuations can affect the structural integrity of the trailer itself. Materials can expand and contract, leading to potential stress points that may compromise safety. By understanding these temperature effects, operators can implement preventive measures to safeguard their trailers and enhance overall safety.

Key Benefits of Effective Temperature Monitoring

Implementing an effective temperature monitoring system offers a multitude of benefits that extend beyond mere awareness of current conditions. By proactively tracking and managing trailer temperatures, operators can enhance performance, safety, and efficiency.

One of the primary advantages is the prevention of equipment failures. Continuous monitoring allows for early detection of abnormal temperature rises, which often signal underlying issues such as friction, misalignment, or insufficient lubrication. By addressing these problems before they escalate, operators can avoid costly repairs and prolonged downtime.

Another significant benefit is the ability to optimize fuel efficiency. Maintaining optimal tire and axle temperatures can reduce rolling resistance, leading to lower fuel consumption. This not only results in cost savings but also contributes to a smaller carbon footprint, making the operation more environmentally friendly.

Additionally, effective temperature monitoring enhances load safety. By ensuring that tires and axles are within their ideal temperature ranges, operators can minimize the risk of blowouts or mechanical failures that could jeopardize the safety of the load being transported. This is especially crucial for sensitive cargo that may be impacted by temperature changes.

Finally, a reliable temperature monitoring system can improve fleet management. With real-time data at their fingertips, fleet managers can make informed decisions regarding maintenance schedules, route planning, and overall trailer management. This not only boosts operational efficiency but also enhances the reliability of service delivery.

Technologies Used in Trailer Temperature Mapping

The evolution of trailer temperature mapping has been significantly influenced by advancements in technology, resulting in highly efficient and reliable monitoring systems. Various technologies work in tandem to ensure that operators receive accurate and real-time data, thereby enhancing the overall safety and performance of trailers.

One of the fundamental technologies employed is infrared thermography. This non-contact method allows operators to measure surface temperatures from a distance, making it ideal for monitoring tire and axle conditions without direct interference. Infrared cameras can quickly identify hot spots that may indicate potential issues, providing valuable insights for preventive maintenance.

Protect your trailer

Another critical component is the use of wireless sensors. These small, lightweight devices are strategically placed on axles and tires to monitor temperature continuously. They transmit data to a central hub or mobile device, ensuring that operators can access real-time information from anywhere. The wireless nature of these sensors also simplifies installation and reduces the need for complex wiring systems.

Additionally, data analytics and machine learning play a pivotal role in enhancing temperature mapping systems. By analyzing historical temperature data, these technologies can identify patterns and predict potential failures before they occur. This predictive capability empowers fleet managers to take proactive measures, ensuring that trailers remain in optimal condition.

Furthermore, GPS integration allows operators to correlate temperature readings with location data. This feature enables them to monitor how environmental factors, such as ambient temperature and road conditions, affect their trailers throughout different routes. Such insights can inform better decision-making regarding route planning and load management.

Best Practices for Implementing Temperature Mapping

Implementing effective trailer temperature mapping requires a strategic approach to ensure optimal performance and safety. By adhering to best practices, fleet operators can maximize the benefits of their monitoring systems.

First and foremost, it is essential to choose the right technology that fits the specific needs of your fleet. Consider factors such as the size of the trailer, the types of cargo being transported, and environmental conditions. Investing in high-quality sensors and monitoring systems can significantly enhance data accuracy and reliability.

Moreover, establishing a regular maintenance schedule for the monitoring devices is crucial. This includes routine checks on sensor functionality, battery levels, and data transmission capabilities. Ensuring that the equipment is in good working condition helps prevent unexpected failures and ensures continuous data flow.

Training staff on the importance of temperature mapping and how to interpret the data is another vital practice. Providing comprehensive training sessions can empower operators to make informed decisions based on real-time data, helping them respond swiftly to anomalies.

Additionally, integrating temperature mapping data with fleet management systems can enhance operational efficiency. By combining temperature data with other performance metrics, fleet managers can gain valuable insights into overall trailer health and make data-driven decisions that optimize routes, reduce downtime, and improve safety.

Finally, it is important to establish a clear protocol for responding to temperature alerts. This includes defining who will be notified in case of anomalies and outlining the steps to take in response. Having a well-structured response plan ensures that issues are addressed promptly, thereby minimizing risks associated with temperature-related failures.

Future Trends in Trailer Temperature Monitoring

The landscape of trailer temperature monitoring is rapidly evolving, driven by advancements in technology and the increasing demand for smarter logistics solutions. As we look to the future, several trends are emerging that promise to enhance the effectiveness and reliability of temperature monitoring systems in trailers.

One of the most significant trends is the integration of Internet of Things (IoT) technology. IoT devices enable real-time data collection and transmission, allowing fleet managers to monitor trailer conditions remotely. This connectivity not only facilitates immediate responses to temperature fluctuations but also contributes to more efficient route planning and cargo management.

Moreover, the use of artificial intelligence (AI) and machine learning algorithms is becoming increasingly prevalent in temperature monitoring systems. These technologies can analyze vast amounts of data to predict potential failures before they occur. By identifying patterns and anomalies, AI can provide actionable insights that help fleet operators take preventive measures, ultimately reducing the risk of costly equipment failures.

Another trend is the emphasis on sustainability and energy efficiency. As regulations around environmental impact become stricter, trailers equipped with smart monitoring systems can help companies optimize their operations by minimizing energy consumption and waste. This not only benefits the environment but also enhances the company's bottom line.

As these trends continue to develop, it's crucial for fleet operators to stay informed and adapt their monitoring strategies accordingly. With the right systems in place, operators can significantly improve safety, efficiency, and overall performance.

Tow with peace of mind, knowing that trailerwatchdog is standing guard.